Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

3-D printer builds heart-on-a-chip device

Device coupling living tissue and sensors could one day screen drugs

by Matt Davenport

October 26, 2016

| A version of this story appeared in

Volume 94, Issue 43

Harvard University researchers may be one step closer to replacing lab rats with lab-grown organ tissue thanks to inky chemistry and three-dimensional printing.

Led by Kevin Kit Parker and Jennifer A. Lewis, the team 3-D printed devices that encourage the growth of heart cells and then electronically monitor the beating of the resulting tissue (Nat. Mater. 2016, DOI: 10.1038/nmat4782).

This is the first time researchers have coupled living tissue with sensor electronics entirely through 3-D printing, Lewis says. Sometimes referred to as an organ-on-a-chip, this type of device could become the basis for future bionic implants and prosthetics but may sooner help evaluate new drug candidates in place of animal models, she adds.

To print its new platforms, the team formulated several functional “inks” for its custom 3-D printer. For instance, the researchers concocted an ink that mixes thermoplastic polyurethane with carbon black nanoparticles to print flexible but conductive sensor loops. Printing these loops between insulating layers of a pure polyurethane ink created layered cantilever structures that could flex like extremely elastic diving boards.

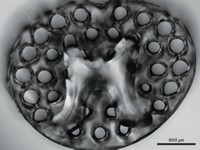

The team capped the cantilevers by printing layers of polydimethylsiloxane with grooves that guided cardiac cells—sourced from rats and generated from human stem cells—to self-assemble into thin layers of pulsating tissue. The tissue’s movement drives the underlying cantilever to bend, altering the conductivity of the sensor loop within.

The loops are connected to external equipment, such as oscilloscopes and power supplies, with the help of a silver-laden ink. This enables devices to convert the tissue’s mechanical beat into an electrical signal.

As a proof of concept, the team showed that its cardiac-tissue-on-a-chip responded to a pair of approved pharmaceuticals—verapamil and isoproterenol—and electronically reported their effects. Verapamil, a medication for high blood pressure, slowed the beating of a device’s cardiac tissue and diminished the strength of its contractions. Isoproterenol, a drug used to treat slow heart rate, increased both the tissue’s strength and beat frequency.

Although it remains to be seen whether such devices can reliably screen novel drug candidates, this work highlights the promise of 3-D printing in creating organs-on-a-chip, says Michael C. McAlpine of the University of Minnesota, Twin Cities. McAlpine’s group 3-D printed a platform for observing how viruses affect neurons last year (Lab Chip 2015, DOI: 10.1039/c5lc01270h).

Researchers developed earlier organs-on-a-chip relying largely on photolithography and other cleanroom fabrication techniques that are often incompatible with living cells, McAlpine says. The Harvard team demonstrated that 3-D printing can build up fully functional devices in a biocompatible way.

“We’ve shown we can go all the way from printing living cells to synthetic materials,” Lewis says, adding the approach can be adapted to produce other types of tissue and sensors.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter