Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Handheld artificial nose sniffs out rotting meat

Detecting meat freshness could reduce food waste and prevent food-borne illness

by Prachi Patel

December 1, 2016

The bacterial decay of meat starts long before you can smell it. But a new palm-sized electronic nose can accurately spot this decay by sniffing gases emitted by rotting meat down to parts-per-billion levels (ACS Sens. 2016, DOI: 10.1021/acssensors.6b00492). The sensor could help cut food waste and prevent food-borne illnesses.

When bacteria break down amino acids in meat, the process releases a mix of sulfide and amine vapors. Spectrometry and chromatography can detect these chemicals, but these methods take time and require large, complex instruments. Electronic nose technologies, which directly sense compounds using electronic sensor arrays, can be more affordable and portable.

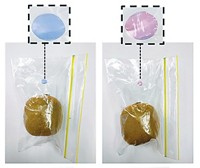

The new handheld device, built by Kenneth S. Suslick and Zheng Li of the University of Illinois, Urbana-Champaign, employs a disposable plastic strip printed with an array of 20 dyes, chosen for their ability to change color when they come in contact with specific chemicals. As mixtures of gases interact with the dyes on the strip, they generate unique color patterns.

The researchers chose to detect four gases emitted by rotting meat: hydrogen sulfide, dimethyl sulfide, trimethylamine, and cadaverine. A digital camera chip analyzes the pattern and intensity of the colors on the strip to determine the concentrations of the different gases. Direct testing of the analytes showed that the device could detect hydrogen sulfide at 8 ppb, dimethyl sulfide at 33 ppb, trimethylamine at 4 ppb, and cadaverine at 7 ppb—levels undetectable by the human nose.

Next, the researchers exposed the sensor to vapors from refrigerated and unrefrigerated beef, chicken, fish, pork, and shrimp samples for two minutes. For meats stored at room temperature, the color pattern changed over the course of four days, indicating gas buildup. For refrigerated meats, the color pattern did not change significantly, indicating slower spoilage. By statistically analyzing tests on multiple samples, the researchers could then use their color test to categorize the meat samples as fresh, less fresh, or spoiled.

In addition to meat inspectors and distributors, Suslick says that consumers could use the device with a smartphone and a special app. He has cofounded a company, iSense, to commercialize the technology.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter