Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Photolithography method creates complex patterns using inorganic nanocrystals as colorful inks

Procedure leads to patterned thin films of metals, semiconductors, and oxides without the need for organic photoresists

by Mitch Jacoby

July 31, 2017

| A version of this story appeared in

Volume 95, Issue 31

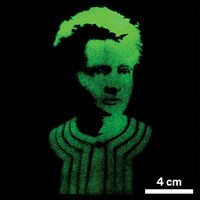

Controlling the surface chemistry of inorganic nanocrystals, also known as quantum dots, has enabled researchers to devise a photolithography process for making all-inorganic patterned thin films. Unlike conventional lithography, the new technique requires no polymeric photoresists. The method, which requires fewer steps and could reduce fabrication costs for electronics, has been applied to metal, semiconductor, magnetic, and oxide nanocrystals (Science 2017, DOI: 10.1126/science.aan2958). Conventional lithography provides electronics manufacturers with a procedure for patterning semiconductors such as silicon wafers, forming millions of circuit elements simultaneously. The patterning relies on a stencil-like photoresist that masks the semiconductor and responds to light, becoming either soluble or insoluble in a given solvent, depending on the specifics of the process. A team led by the University of Chicago’s Dmitri V. Talapin has built that photosensitivity directly into quantum dots by functionalizing them with light-sensitive capping ligands. The researchers apply colloidal quantum dot solutions as colorful inks to various substrates, then expose select regions of the films to UV light, making those regions insoluble in a chosen solvent. Then they wash away the unexposed, soluble regions. For example, the team has drawn complex patterns from solutions of red CdSe/ZnS, green InP/ZnS, and blue ZnSe/ZnS quantum dots all capped with NH4CS2N3 ligands, which decompose under UV light.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter