Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Self-folding electronics take shape

A mechanically active ink causes flat, 3-D-printed electronic components to spontaneously fold

by Katherine Bourzac

September 11, 2017

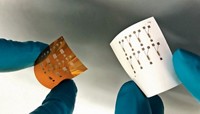

After being peeled from the platform of a three-dimensional printer, a flat electronic component begins to fold its four legs into position. In just a few minutes, it is fully formed and can stand. Researchers can now print self-folding electronic devices like this one thanks to a new polymer ink that builds up mechanical strain during the 3-D-printing process (ACS Appl. Mater. Interfaces 2017, DOI: 10.1021/acsami.7b10443).

Using 3-D printing allows engineers to make objects rapidly. But making electronic devices that have unusual 3-D shapes is quite challenging, says Subramanian Sundaram of Massachusetts Institute of Technology, who developed the new ink in collaboration with Ryan C. Hayward, a polymer scientist at the University of Massachusetts, Amherst.

Semiconductor inks must be printed on a flat surface or else they will dribble out of bounds and become smeary because of the runny solvents used to make them. Researchers typically print electronic devices flat, then reshape them into a 3-D form. Methods for reshaping these flat components include heating and bending, or using printable materials that expand in the presence of water or another solvent. But exposure to liquids and heat isn’t good for electronics, Sundaram says.

He and his colleagues discovered their folding ink by accident while testing materials in their lab-built 3-D printer. Plastic parts usually shrink after they’re cured or solidified with ultraviolet light, but the researchers noticed that one of their inks did the opposite. “You could see it expand in front of your eyes,” Sundaram says.

The ink they developed is made up of long-chain and short-chain acrylic polymers. As the 3-D printer deposits layers of ink on top of one another, the short polymer chains from one layer migrate into the underlying, partially cured layer deposited earlier, like water soaking into a sponge. During that absorption, the ink layers swell, causing mechanical stress to build up within that polymer as it becomes rigid. The residual stress cannot be released until the printed piece is pried off the substrate.

To make a self-folding device, the researchers alternate layers of the folding ink with rigid polyacrylate. By controlling different parameters such as the ratio of long and short polymer chains in the ink, the intensity of the UV light, the temperature of the curing step, and the thickness of the ink layer, the researchers could program particular folds into a printed object and control the folding angles within a few degrees. As a proof of principle, the group made a self-folding four-legged electrochromic device, which changes color in response to an applied voltage.

“The idea of using mechanically active substrate materials to transform planar electronics into 3-D, curvilinear shapes is interesting,” says John A. Rogers, a materials scientist at Northwestern University. With further development, he says, researchers could use this method to make bio-inspired devices and medical devices.

Sundaram says they hope to use 3-D printing to build microsystems and robots that can assume complex shapes. To make that happen, they’re developing printable materials for moving parts.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter