Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Why efforts to use green fuels sometimes run afoul

Some microbes thrive on biofuels and can contaminate fuel equipment and clog engines

by Mitch Jacoby

March 5, 2018

| A version of this story appeared in

Volume 96, Issue 10

Most people exercise a healthy dose of caution when handling fuels like gasoline and diesel. Health-wise, they know you shouldn’t deeply inhale the fuels’ vapors or splash the liquids on your skin. Ingesting them is out of the question.

But it turns out that not everyone avoids contact with fuels: Some microbes love the stuff. In fact, various microorganisms thrive on gasoline and diesel fuel, substances that are clearly toxic to humans and animals. Unfortunately, this bug love can lead to fuel contamination, clogged or fouled equipment, and if left unchecked, even engine failure.

Scientists have long known about the threat of microbial fuel fouling. But they have more cause for concern now that the popularity of biofuels, such as biodiesel, is on the rise. Some bacteria and fungi crave the generous quantities of fatty acid compounds that make up biofuels.

Private motorists have little to worry about because they tend to use and replace small quantities of fuel frequently. But for airlines and other organizations that store enormous quantities of fuel, contamination could be a problem. For the U.S. Air Force, which has a mandate to rely increasingly on biobased fuels, extreme caution is in order.

That’s why Wendy J. Goodson studies the effects of microorganisms on Air Force weapons systems and fueling infrastructure. Goodson leads a research group at the Air Force Research Laboratory at Wright-Patterson Air Force Base in Ohio. Together with collaborators, these researchers are studying the effects of fuel biocontamination, the factors that promote this type of degradation, and improved ways of detecting it. They’re also zeroing in on the identities and genomes of the troublemaking organisms and devising ways of stopping them in their tracks.

Although people may find it surprising that some microorganisms happily eat engine fuels, it’s not exactly a secret. “Biodeterioration of fuels has been known and studied for more than a century,” asserts Frederick J. Passman, a consultant who specializes in controlling microbial contamination.

The earliest study, which focused on biocontamination of gasoline, was published in 1895 in a German-language journal, Passman says. And most of the follow-up studies were published in the microbiology literature, “not in the sort of journals likely to be read by petroleum engineers and organic chemists,” he adds.

Goodson concurs. She says fuel maintenance specialists were aware that fuel could become contaminated and fouled with biological growth, but the possibility seemed remote and “resided in the background of people’s knowledge and concern.” That led to some troubles for the military.

A decade ago, as the Air Force prepared to ramp up its use of bioderived fuels to comply with green energy initiatives developed during the George W. Bush administration, researchers examined alternative fuels for materials compatibility, Goodson says. They were confirming, for example, that the fatty acid methyl esters that are found in biodiesel would not react adversely with materials in fuel tanks, hoses, pumps, O-rings, and other fueling equipment.

“But they did not consider the effects of microbiology on the fuel system,” she notes. That’s because most fuels used by the Air Force and other organizations in the past 50 years—meaning petroleum-derived fuels—are not overly susceptible to biofouling.

Fleet operators don’t normally use pure biodiesel as a transportation fuel. It’s expensive, can gel at low temperatures, and may void some engine manufacturers’ warranties. So to go green, the Air Force began using blends of conventional diesel and biodiesel in its trucks and other ground vehicles.

Eventually, though, that led to contaminated storage tanks, plugged fuel filters, and other problems not commonly seen before the fuel switch, Goodson says. As a result, some fuel experts pooh-poohed the idea of using alternative fuels, concluding that “bio” meant “bad.”

Not so, Goodson contends. “There are a whole set of conditions—biological, physiological, and environmental—that have to be met to set off the perfect storm of fuel degradation.” Preventing fuel fouling calls for evaluating those details thoroughly. And given that worldwide biodiesel production is on the rise—the Organisation for Economic Co-operation & Development projects an increase from 31 billion L in 2015 to 41 billion L by 2025—the U.S. military isn’t the only organization that needs to consider the effects of microbiology on fuels.

The common denominator in biocontamination of fuels, alternative and conventional alike, is water. As Passman explains, the reason is simple: Water is an essential factor for microbial activity. Yet preventing its accumulation in fuel systems is difficult.

Hot fuel leaving a refinery reactor is sterile, but it doesn’t stay that way. While sitting in tanks and pipelines, which aren’t airtight, fuel comes into contact with air and water vapor. As the fuel cools during shipping or in storage at tank farms, water becomes less soluble and condenses.

Even when tank farm operators follow best housekeeping practices, the condensed water, which is more dense than fuel, accumulates at the bottoms of tanks and low points in pipelines, forming habitats in which fuel-feeding microbes can thrive. “The volume of accumulated water may seem trivial to an engineer, but it’s an ocean to a microbe,” Passman says.

Water problems can be even worse in underground storage tanks and worse still in ones that hold biodiesel, which is more hygroscopic and therefore absorbs more water than conventional diesel does. So underground biodiesel tanks are exactly where a team led by Goodson and University of Oklahoma microbiologist Bradley S. Stevenson recently focused their attention.

In a yearlong study, the team examined the growth of microbial communities and the extent of bioinduced corrosion in several large underground storage tanks at two U.S. Air Force bases. The study was unique in that it quantitatively probed microbial activity in tanks that were actively in service—specifically, they were being used to store and dispense B20, a commercial biodiesel blend composed of 20% fatty acid methyl esters and 80% conventional ultra-low-sulfur diesel.

To look for microbial activity, the researchers immersed polymer-coated metal plates—simulating the materials that storage tanks are made of—to various depths in the tanks. They withdrew and analyzed them at regular intervals. They also collected fuel samples from the bottoms of the tanks and compared them with reference samples taken directly from fuel-delivery trucks.

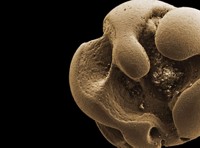

What they found was that several microorganisms were wreaking biohavoc in the tanks. The list includes Acetobacteriaceae and other types of bacteria, as well as various yeasts, including Candida and Pichia. But the most prevalent microbe, and the worst actor by far, was a filamentous fungus of the genus Byssochlamys, a microorganism known to cause food spoilage. That bug, with a little help from its friends, caused the metal plates to visibly foul—become coated with orange and red slimy films—and led to fuel samples that showed varying degrees of turbidity and slime accumulation.

The study, which the team has not yet published, also showed that the most heavily fouled plates were the most pitted and corroded ones and that corrosion correlates with levels of fuel acidification. When microbes decompose the fatty acid compounds in the biofuels, they generate organic acids and CO2, species known to promote corrosion.

Now that the researchers know which bugs are the troublemakers, they are studying ways to control them. They are also aiming to understand relationships among coexisting microorganisms. As an example, Stevenson explains that the metabolic product of one microbe might be the energy source for a different microbe in that community. Such information could be helpful in combating fuel fouling.

Elsewhere at AFRL, biologist Oscar N. Ruiz works with collaborators at the University of Dayton Research Institute to fight fuel fouling in other ways. They use genomics methods to understand the molecular machinery in microbes that enables them to metabolize fuel. That’s the first step in mitigating the problem, Ruiz says.

A few years ago, Ruiz and coworkers studied Pseudomonas aeruginosa, a bacterium that readily decomposes jet fuel alkanes, especially those in the C11–C18 range. To thrive, the microbe needs to protect itself from toxic aromatic and cyclic hydrocarbons also found in jet fuel.

It turns out that P. aeruginosa uses efflux pumps, protein transporters in cell membranes, to drive the poisonous jet fuel components out of its cells. Armed with that information, the team showed that a peptide-based molecule could shut down the organism’s efflux pumps and prevent the bacteria from growing in jet fuel (Environ. Sci. Technol. 2013, DOI: 10.1021/es403163k). Compared with treating the fuel with a biocide that’s toxic to people, the peptide strategy, for which the team filed a patent, provides a distinct safety advantage.

To gain the same type of molecular upper hand over other fuel-degrading microbes, Ruiz and coworkers recently sequenced the genomes of several previously uncharacterized strains of microbes that they isolated from fuel environments. The list includes a strain of Nocardioides luteus, an alkane-degrading bacterium collected from soil polluted with a type of jet fuel called JP-7; Fusarium fujikuroi, a fungus recovered from Jet A fuel; and Pseudomonas stutzeri strain 19, a Gram-negative bacterium that metabolizes aromatic hydrocarbons.

“This type of biodegradation is like a fuel disease,” Ruiz says. The first step in controlling it is understanding the microorganism that causes the disease. That means determining the fuel components that a microbe is capable of decomposing and then identifying the genetic basis for that metabolic function.

Microorganisms exist everywhere, including in fuel and fuel systems, Goodson says. There are many circumstances under which they will cause a degradation problem and plenty under which they won’t.

Sorting through the good guys, the bad guys, and all the fuel types is a major project, but Goodson doesn’t let the complexity of the project bug her. “That’s the puzzle I like to work on,” she says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter