Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Recycling

Solar panels face recycling challenge

Researchers and companies are preparing for a looming tsunami of photovoltaic waste

by Mark Peplow, special to C&EN

May 22, 2022

| A version of this story appeared in

Volume 100, Issue 18

Credit: Shutterstock | The growing burden of silicon solar panel waste has researchers looking for solutions

In brief

The world’s photovoltaic capacity is growing at a record pace—and so too is the burden of waste from solar panels that have reached the end of their working lives. Many of these dead panels are dumped in landfills, even though they contain valuable elements such as silicon, silver, and copper. Researchers are now racing to develop chemical technologies that can help dismantle solar cells and strip away the valuable metals within. Others are reprocessing the cells’ silicon wafers so that they can be turned into fresh batches of solar-grade silicon. Several European projects aim to make these kinds of processes commercially viable in the next few years. Recovering more of these materials at high purity could make recycling a more economically attractive option than consigning this waste to an indecent burial.

Solar power is booming. Global photovoltaic capacity grew from 1.4 GW in 2000 to 760 GW in 2020, and solar power now generates almost 4% of the world’s electricity, according to the International Energy Agency. But experts say this astonishing growth in low-carbon power is also a ticking time bomb.

More than 90% of photovoltaic (PV) panels rely on crystalline silicon and have a life span of about 30 years. Forecasts suggest that 8 million metric tons (t) of these panels will have reached the end of their working lives by 2030, a tally that is projected to reach 80 million t by 2050 (Nat. Energy 2020, DOI: 10.1038/s41560-020-0645-2). But today’s technologies for recycling these units are inefficient and rarely deployed.

That is an enormous problem. PV panels contain toxic materials, like lead, that can cause environmental pollution, yet many are dumped in landfills when they die. They also contain valuable materials that could be reused to make new solar cells, but today these resources are mostly wasted.

In the US, there are no federal regulations to mandate PV recycling, and according to the US National Renewable Energy Laboratory, less than 10% of the country’s decommissioned panels are recycled. Even in the European Union, where legislation requires PV recycling, many waste facilities merely harvest bulk materials like aluminum frames and glass covers, which make up over 80% of a silicon panel’s mass. The remaining mass is often incinerated, even though it contains elements like silver, copper, and silicon, which together account for two-thirds of the monetary value of a silicon panel’s materials.

Companies and researchers are now racing to prepare for the looming tsunami of PV waste. They are developing technologies that promise to recover far more of the useful materials from cells while reducing the costs and environmental impacts of recycling. NREL says that it costs about $15–$45 to recycle a silicon PV module in the US but only $1–$5 to dump it in a landfill. So cheaper processes that extract more economic value from PV waste—alongside more restrictions on landfilling—could help tip the balance in favor of recycling (Nat. Energy 2021, DOI: 10.1038/s41560-021-00888-5).

These efforts are also vital for the future of the PV industry itself. Those who oppose new solar installations sometimes cite concerns about the challenges of decommissioning PV panels, says Garvin Heath, an environmental scientist at NREL. “The photovoltaic industry’s license to operate is built on the reputation of a green technology,” he says. “If you have an end of life that doesn’t look like it fulfills that promise, I think it becomes more vulnerable. We have to address these problems.”

Tough challenge

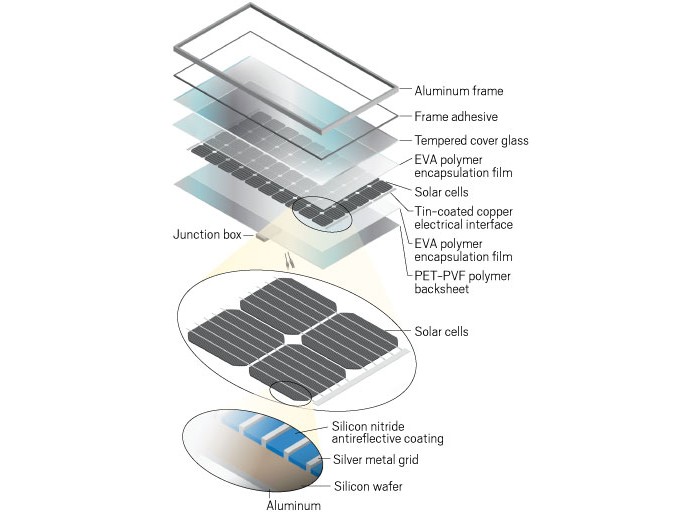

There are thousands of models of silicon PV panels, but they generally share the same basic design. Their solar cells contain a sandwich of aluminum, silicon, and silver wires. Multiple cells are connected into modules by copper wires that are soldered with tin and lead. These modules are encapsulated in layers of glue-like poly(ethylene-co-vinyl acetate) (EVA), covered with a back sheet of polyethylene terephthalate (PET) and poly(vinyl fluoride) (PVF), topped with glass, and surrounded by an aluminum frame. The modules are then connected into full-size panels.

This robust, weatherproof design keeps modules functioning for decades, but it also makes them difficult to disassemble. “The problem with end-of-life modules is that they were not intended to be dismantled, and that’s a major drawback,” says Guy Chichignoud, chief technical officer of ROSI Solar, a French company involved in PV recycling.

More panels, more waste

Removing the aluminum frame and the electrical junction box is the easy part, and a lot of PV recycling stops there. It’s trickier to tease the glass cover away from the solar cells beneath, so recyclers often simply shred this portion and sell the contaminated glass as low-value granules, or cullet. More challenging still is to separate the silver and other metals from the cell to recover a clean silicon wafer.

No commercial recycling process can yet recover all these useful materials from a PV panel, and there is no consensus about the best way to achieve that goal, says Meng Tao of Arizona State University, who works on PV recycling. “The recycling technologies we have today are still rudimentary,” he says.

In the EU, legislation requires PV manufacturers to recycle waste panels and recover at least 80% of their mass, an effort largely organized through an industry consortium called PV Cycle. In 2018, French waste management company Veolia opened a dedicated PV recycling facility to process this waste, recovering bulk materials and low-grade silicon.

If more materials could be recovered at a higher purity, they would have a greater market value and make recycling more economically attractive. But extracting high-purity materials also tends to require more processing steps, increasing costs. Solving this dilemma could be the key to developing a sustainable PV recycling industry, Tao says.

Modules could also be redesigned for easier disassembly, Chichignoud adds, although it would take decades for such improvements to reach recycling plants.

Unmaking the sandwich

For now, one of the key challenges is to unstick a module’s glass from its solar cells. “If there’s any breakthrough technology in this area, it will be an easier way to get rid of the glue layer,” says PV recycling expert Rong Deng of the University of New South Wales.

Some researchers have used organic solvents to eliminate the EVA, but this is an expensive tactic that could generate large amounts of hazardous waste (Resour., Conserv. Recycl. 2020, DOI: 10.1016/j.resconrec.2020.105241). Instead, some commercial recyclers burn off the EVA and other polymers in an oven at roughly 500 °C. But putting batches of 1 m wide PV modules through this pyrolysis process takes a big oven—and a lot of energy.

A third method uses infrared heaters and a vibrating knife to slice a panel’s glass away. One version of this process emerged from an EU-funded research consortium called FRELP (Full Recovery End of Life Photovoltaic), which ran from 2013 to 2016. Tialpi, an Italian recycling company, is using this method at a PV recycling plant that cost €2 million ($2.3 million) to set up and will open in the next few months. It aims to handle 5,000 t of panels per year. The freed glass will be sorted into different quality grades and sold to the glass industry. The plant should be able to recover about 85% of the mass of a PV panel, including the glass, aluminum frame, and external electrical cables, says Tialpi’s technical director, Lodovico Ramon.

After recyclers get past the glass, they can focus on harvesting the higher-value materials beneath. FRELP developed chemical processes that could recover silicon and metals from the cells, for example. These involve using nitric acid to leach the metals, followed by an electrochemical process called electrowinning that separates silver and copper from the mix. Ramon says the method works well, but Tialpi would need to process 20,000 t of panels per year for it to be cost effective in a commercial operation.

Arizona State University’s Tao is developing a selective leaching and electrowinning process that he hopes to demonstrate at pilot scale through a spinout called TG Companies. He eschews nitric acid and instead uses other leaching agents—which remain a commercial secret—to help recover more than 99% of the silver from waste cells (Prog. Photovoltaics 2020, DOI: 10.1002/pip.3316).

Deng avoids a leaching step altogether and instead uses the solar cell itself as an electrode in an electrochemical cell. The other electrode is a silver wire, and the aqueous electrolyte between them contains silver nitrate and potassium nitrate. Applying a current removes silver from the solar cell and deposits it on the wire. This lab-scale process recovers 95% of the silver at 99.9% purity in a few minutes, and the benign electrolyte can be reused for at least 80 cells, potentially giving it a much lower environmental impact than its rivals, Deng says (Green Chem. 2021, DOI: 10.1039/d1gc02263f).

The price of purity

Once metals have been stripped away from a cell, all that remains is a silicon wafer less than 200 µm wide. Producing new wafers accounts for about half the energy used to make a solar module, so reusing silicon from old panels could dramatically reduce the carbon footprint of the PV boom. Some researchers have argued that wafers could even be recovered intact and inserted into new PV cells. But Deng says that few manufacturers are willing to use 30-year-old wafers in their products, given the enormous improvements in solar technology over the past few decades.

Unfortunately, old wafers cannot simply be melted and re-formed into new cells. Aside from traces of silver and aluminum, they also contain dopants such as boron and phosphorus, along with a silicon nitride antireflective coating. Removing this contamination is a crucial step toward making PV recycling economically sustainable. Metallurgical-grade silicon, with a purity of about 99%, costs roughly $4 per kilogram. But solar-grade silicon has a minimum purity of 99.9999%—known as “six nines,” or 6N purity—and costs at least eight times as much. In 2020 and 2021, explosions at silicon production plants in China exacerbated a shortage that has sent solar-grade silicon prices soaring above $30 per kilogram.

Advertisement

Several European projects launched last year to unlock this value by extracting high-purity materials from dead PV panels. Backed by €8.4 million in EU funding, the Photorama consortium will build an automated pilot facility to disassemble PV panels, recover more than 98% of their mass, and process those materials to more than 98% purity. “The main goal is to extract all the valuables from PV panel waste, of all kinds,” says Ana Maria Martinez of Norwegian research organization Sintef, a partner in Photorama. “It’s about reusing everything.” One of its innovations will be a new delamination process that uses an as-yet-unspecified supercritical fluid, which could allow glass to be removed intact and reused in new PV modules. The project also plans to use ionic liquids in their metal leaching process.

A second project, ReProSolar, won €4.8 million from the EU to establish a pilot recycling plant that can process 5,000 t of panels per year by 2023. One of the key partners is ROSI, which uses a mild base to remove silver from the cells—not by dissolving the metal but by gently etching away the silicon around the silver wires so that the wires can be retrieved whole. Chichignoud says ROSI has found that the silicon wafer can then go directly into the conventional system for purifying silicon to solar grade, known as the Siemens process, without first extracting dopants or silicon nitride.

The Siemens process typically combines metallurgical-grade silicon with hydrogen chloride gas at 300 °C to form trichlorosilane (SiHCl3). This is distilled away from impurities and then reacted with hydrogen gas to form polycrystalline silicon, composed of many tiny crystallites, with a purity of 6N up to 8N. This material is often re-formed into large, single crystals—monocrystalline silicon ingots—that then get sliced into wafers for solar cells. And that produces another source of waste: during cutting, roughly 35% of the silicon is lost as fine particles called kerf. Most kerf is currently landfilled or used as a low-grade alloying compound.

ROSI is involved in a third consortium called Icarus, which has €10 million in EU funding to reuse kerf and other waste from the energy-intensive wafer production process. ROSI is developing a chemical process to turn kerf into 4–5N silicon that could take the place of the 2N metallurgical-grade silicon in the Siemens process. Using this higher-purity feedstock should reduce the energy demand of the process and improve its overall yield of polysilicon, Chichignoud says.

If Icarus and the other European projects can extract valuable materials from PV waste, it could help entice more companies to establish silicon and photovoltaic manufacturing plants in Europe, says Martin Bellmann, senior business developer at Sintef, which is the coordinator of Icarus. “There is a big ambition to reestablish the PV manufacturing industry in Europe, and I think this would contribute,” he says.

A question of responsibility

Meanwhile, silicon PV recycling in the US is still in its infancy. In 2016, the US Solar Energy Industries Association launched a voluntary recycling program, similar to Europe’s PV Cycle, and a handful of companies offer PV recycling services.

Perhaps the most experienced PV recycler in the US is First Solar, a company that manufactures cadmium telluride panels, which account for about 3% of global solar capacity. The company has been recycling its panels since 2005 to recover toxic cadmium and other components. Back in 2018, First Solar told C&EN that it might move into silicon PV recycling, although no plans have been made public, and First Solar did not respond to interview requests for this story.

China is the biggest unknown in PV recycling. It hosts almost one-third of the world’s working PV capacity, much of it located in the remote northwest of the country, making it expensive to collect and reprocess end-of-life units. Chinese researchers reported in 2019 that the country had no policies or regulations around the recycling of PV panels and that it would have millions of metric tons of PV waste by 2030 (Int. J. Sustainable Eng. 2019, DOI: 10.1080/19397038.2019.1674940). But Chinese PV manufacturers recently launched a consortium—the China EcoPV Alliance—to improve the sustainability of the entire PV supply chain, although details are scant. China’s government has been funding research on recycling technologies, NREL’s Heath says, but little of this work has been published.

Aside from technological improvements, regulations and innovative business models can both play a crucial role in encouraging PV recycling around the world. In the US, new regulations in Washington State stipulate that from July 2023, PV modules cannot be sold there without the manufacturer or retailer having a state-approved plan for end-of-life reuse or recycling. Meanwhile, a European project called Circusol is investigating whether manufacturers could retain ownership and responsibility for solar panels throughout the cells’ lives—effectively renting the panels to users as a service.

Researchers, companies, and governments should work together to improve PV recycling so that it can recover all the constituent materials at their highest possible value, Heath says. But it is also important to use whatever tools we have today to tackle the rising tide of waste. “Even if we were to only focus on the top four constituents in mass composition and value—aluminum frame, glass, silicon, and silver—you wouldn’t have that much left to bury,” he says. “I’m not calling for that, but you would be taking care of well over 90% of the mass of your modules. And that’s a heck of a lot better than burying the whole thing.”

Mark Peplow is a freelance writer based in Penrith, England. A version of this story first appeared in ACS Central Science: cenm.ag/solar-recycling.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter