Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Microscopy

Machine learning spots metals in single-atom catalysts

A novel image analysis method accelerates the detection of metal atoms on heterogeneous catalysts and reduces human error

by Fernando Gomollón-Bel, special to C&EN

May 11, 2022

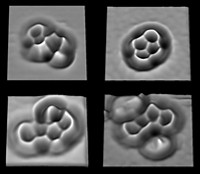

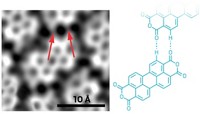

An algorithm could accelerate the way chemists identify and analyze single-atom catalysts (J. Am. Chem. Soc. 2022, DOI: 10.1021/jacs.1c12466). Using machine learning techniques, the method scans microscopy images and successfully detects metallic atoms. Researchers expect this technique will reduce human biases in image selection and characterization, as well as improve the understanding of heterogeneous catalysts.

The standard method of identifying individual metal atoms on the surface of a catalyst involves a human expert analyzing high-resolution images taken with scanning transmission electron microscopy (STEM). “Microscopy is the most conclusive technique to confirm the presence of metal atoms supported on catalysts, because you directly see them,” explains lead author Sharon J. Mitchell, a chemist at the Swiss Federal Institute of Technology (ETH) Zurich. However, the method is prone to human biases and has long processing times.

To better predict a catalyst’s behavior, Mitchell and her team had created hundreds of STEM images of a carbon surface peppered with platinum atoms, each of which could potentially catalyze chemical reactions. But trying to spot the individual catalysts by hand would have been time consuming. They considered whether machine learning, which has been used for other types of image analysis before, could help.

Darío García-Gasulla, an artificial intelligence expert the Barcelona Supercomputing Center, agreed to work with Mitchell’s team. He wanted to find new applications for machine learning methods his team had developed, and he jumped at the opportunity to branch out into chemistry. “AI models were always a tool, never an end”, he says. “It is time now to apply these models to challenges from other disciplines.”

The algorithm the team designed learned how to recognize individual atoms in micrographs by detecting differences in contrast. In STEM, heavier elements appear brighter than lighter ones, which meant the atoms of platinum contrasted clearly against the carbon surface in the images used to train the algorithm.

On average, microscopists need 30 min to process and label the metal atoms in an STEM image like the ones in the study. The algorithm takes a few minutes or even seconds for the same task, says Núria López, a computational chemist at the Institute of Chemical Research of Catalonia, who also collaborated on the work. It also broadens chemists’ capabilities by, for example, identifying atoms that are too difficult for the human eye to distinguish and providing atom distribution maps, she adds.

Stig Helveg, a physicist from the Technical University of Denmark who was not involved in the work, says the speed of the machine learning approach makes it realistic for chemists to analyze a statistically significant amount of surface area. Eventually, computerized microscopes could get feedback from the algorithm and analyze samples without human input, he says. “Even expert microscopists get tired; computers don’t.”

Nevertheless, Helveg notes some limitations, such as the difficulty of detecting stacked clusters of atoms and distinguishing elements with comparable atomic weights. To solve this, researchers could analyze images taken with other techniques, like spectroscopy, with the algorithm and pair them with the STEM images, he says.

Mitchell confirms that they’re already working on more sophisticated versions of their method. The team’s machine learning program is publicly available through an open access license, so microscope manufacturers can already implement it as part of their imaging software, the researchers say.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter