Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biological Chemistry

Go with the Flow

Key challenges remain in microfluidics research an development even as applications advance

by CELIA M. HENRY, C&EN WASHINGTON

March 28, 2005

| A version of this story appeared in

Volume 83, Issue 13

Microfluidics may not yet have caught on commercially to the extent expected by some researchers and investors in the 1990s, but that's not stopping researchers from continuing to develop new devices and applications. A standing-room-only audience heard that message at a symposium on current applications and future directions in microfluidics, held at the Pittsburgh Conference earlier this month in Orlando, Fla.

Andreas Manz, a professor of analytical chemistry and head of the Institute for Analytical Sciences in Dortmund, Germany, told the audience that he originally planned to make "cynical remarks" about the commercial acceptance of microfluidics, but he changed his mind and instead renamed his presentation "fun stuff from the Manz lab." He proceeded to describe a hodgepodge of projects that his group is working on without worrying about whether they will ever be commercialized. He has developed devices ranging from dry-powder dispensers to X-ray fluorescence (XRF) chips.

In the XRF device, Manz and Eduardo D. Greaves, a professor in the laboratory of nuclear fission at Simon Bolivar University in Caracas, Venezuela, incorporate an XRF source for a detection method right on the chip (Lab on a Chip, published online Feb. 18, http://dx.doi.org/10.1039/b415836a). Americium-241 decays to neptunium-237. The X-rays generated can be used for XRF measurements. The device only generates 900 nanocuries of radiation, so special radiation safety precautions are unnecessary. The device has been used to detect tin, zinc, and nickel, Manz said.

For D. Jed Harrison, a chemistry professor at the University of Alberta, Edmonton, one of the challenging areas includes sample preparations for mass spectrometry. His group is expanding the number of samples that can be prepared simultaneously. For a device that handles a single sample, the speed gained by going microscale is only a factor of two or three. Going faster still requires the ability to process multiple samples simultaneously, he said.

Toward that end, Harrison's graduate student Justine Taylor developed a 20-channel multiplexing chip, but the device had some trouble with fractionating samples. Improving on that work, another student, Zhen (Jane) Wang, designed a "fractionation tree" that uses sheath flow around the central flow to protect the channels from leaking. At first, the necessary voltages were too high for practical devices. By changing their fabrication method, they reduced the voltage by about half. They've used the fractionation tree with isoelectric focusing to analyze samples of the proteins avidin and albumin. The group wants to build a similar device with 20 to 40 channels that they can interface to a mass spectrometer. Development has been "difficult but worthwhile," Harrison said.

Of particular interest is the development of new microfluidic pumping methods, an area in which Manz and Harrison are working.

After investigating other pumping methods for cyclic separations (a method in which analytes are separated as they go around a circle multiple times), Manz has had some luck with a simple method involving two parallel plates. Just moving one of the plates pumps the fluid between them. If a chromatographic stationary phase is placed on the moving plate, material from the mobile phase is retained on the stationary phase. Unfortunately, when the moving plate reaches the end of the stationary plate, pumping also stops. Manz solved this problem with a spinning system that uses a circular microfluidic channel in a rotating plate. In addition, Manz is testing whether two independent stationary phases, one on each plate, would be useful, particularly if they selectively retain different analytes.

Harrison is developing a different pumping method, known as magnetohydrodynamic pumping. Development has been challenging, Harrison acknowledged.

Magnetohydrodynamic pumping uses the force generated by a magnetic field--known as the Lorentz force--to generate a flow. Unfortunately, as the device gets smaller, the force decreases as well. Harrison uses 10-m channels with rectangular cross-sections to maximize the force density.

There were other complications. When the magnetic field is generated with an alternating current, bubbles are created as eddy currents heat the liquid. Harrison solved that problem by using direct current. Jian-Bin Bao, a postdoc in Harrison's lab, decided to use gold nanoparticles to carry the high current and reduce the amount of heat generated by the process. Harrison didn't expect the tactic to work, but it did. When Bao tried to reproduce the experiment in other microchip designs, however, he could not duplicate the results.

Using experimental setups that were easier to fabricate, they examined how the conductivity of the gold nanoparticles worked in the first place and why subsequent attempts were unsuccessful. First, they made simple gold foil electrodes with a millimeter-sized spacer. Then they tried an open-cell design in which gold wires were patterned 10 m apart. Gold nanoparticles were included in each of the experimental designs. They still couldn't reproduce the results in either geometry initially.

To figure out the conditions necessary to start the conductance, they applied cyclic voltammetry to the 10-m device. Cyclic voltammetry allowed them to repeatedly cycle the voltage until conduction occurred, providing information on the necessary voltage and the amount of time required at that voltage to initiate the process.

Even with cyclic voltammetry, Bao initially got only a minimal current. "Then, bam, he got a huge current," Harrison said. Harrison suspects that the need for initial cycling before the current flows is due to the gold nanoparticles undergoing nucleation, following which the system becomes conductive.

The current seems to be the result of nanowires that grow across the channel, Harrison said. It only happens when the channel is narrow. When a magnetic field is applied, the wires are not visible, possibly because the wires break and re-form continuously, Harrison said. If the surface is rough, lower voltages are required to initiate the conductivity. Below a certain threshold distance between the gold wires, the voltage necessary for conductivity is apparently independent of the size of the gap, according to the preliminary data. "The pieces are still coming into place," Harrison said, "but now we understand the conductivity."

In addition to work on the components of microfluidic systems, applications of such systems were also discussed in the symposium.

Medical testing is one area in which microfluidic devices should have a big impact. Mark A. Burns, a chemical engineering and biomedical engineering professor at the University of Michigan, is hard-pressed to think of a medical test that couldn't be performed in a microfluidic format.

AT PITTCON, he described an "embarrassingly simple" device--just a channel--for measuring blood viscosity, a cardiovascular risk factor. The blood flows through the device under a capillary pressure-driven flow. By timing how long the blood takes to reach different points in the channel, Nimisha Srivastava, Burns's student who developed the device, can calculate viscosity from a plot of velocity multiplied by the length of the channel versus time. Because a single run takes less than three minutes, she doesn't need to worry about the blood clotting and affecting the viscosity.

Burns also called attention to more complicated devices for genetic analysis that incorporate polymerase chain reaction (PCR) amplification, enzyme digests, and separation. The chip that he described was designed for influenza, but he sees it as a general device. Different genetic analyses just require changing the reagents--what Burns called the "wetware."

For the thermal cycling required by PCR, the chip needs sealed chambers that prevent evaporation. Burns's student Rohit Pal fabricated heaters and temperature sensors for wax valves directly on the chip. Each valve has three or four heaters that melt the wax so it can be moved to open or close the chamber. After PCR amplification, restriction enzymes are used to cut DNA at specific sequences. A publication about the device has been submitted to Analytical Chemistry.

The current device costs Burns about $7.00 to make (about $20 with detectors). Although large-scale production should significantly reduce this cost, he suspects that the most likely way to further reduce the cost is by making more and smaller devices on each silicon wafer.

FLUORESCENCE detectors can be external to the device or directly integrated on the chip, according to Burns. "From a scientific point of view, there are lots of reasons to put detectors on a chip. You can get incredible spatial resolution," he said. "If the fabrication for the detector doesn't adversely affect the rest of your fabrication, then it's a positive thing to do." Ultimately, he said, the choice will come down to cost.

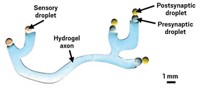

David Beebe, an associate professor of biomedical engineering at the University of Wisconsin, Madison, uses microfluidic devices to re-create cellular environments. "Every cell has the same genome but responds differently," he said. "That response depends on the microenvironment."

Beebe is designing devices that can be used for cell culture in fertility clinics. The methods for culturing cells in vitro haven't changed much since they were first introduced early in the 20th century, he said. One of the steps for in vitro fertilization involves removing from an oocyte a layer of cells called the cumulus cells. Current methods for removing these cells, known as vortexing or handstripping, are harsh and probably contribute to the low success rate of in vitro fertilization methods, Beebe said.

Beebe has found that, with the microfluidic device, more embryos survived to the eight-cell stage of development, an experimental end point that encompasses the developmental stages likely to be affected by removal of cumulus cells. Furthermore, transcription of mRNA increases gradually after treatment with the microfluidic device; by contrast, gene expression spikes with vortexing. Beebe suspects that activation of repair pathways is causing the increased gene expression.

Culturing cells in microchannels provides development kinetics similar to those under natural conditions, as well as higher development efficiencies, Beebe said. He expects to see the microchannel method being used in human in vitro fertilization clinics in the near future.

At the same symposium, J. Michael Ramsey, a chemistry professor at the University of North Carolina, Chapel Hill, and another pioneer in the field of microfluidics, asked the question, "What is left?" He lamented that support for microfluidics from some funding agencies has become scarce at a time when plenty of important work remains to be done.

RAMSEY HIGHLIGHTED needs in technology and applications development, as well as in fundamental research. Fabrication, pumping, and detection technologies are areas where he sees needs. In a number of applications, including genomics, proteomics, environmental monitoring, and synthesis, the potential of microfluidics still hasn't been fully tapped, he said.

Although there's still work to be done in microfluidics, nanofluidics may be the direction of the future, according to Ramsey. To demonstrate what can be done with nanofluidics, he described the electrohydrodynamic separation of 100-base-pair and 1,000-base-pair DNA, which have hydrodynamic radii of 25 and 75 nm, respectively. When the fluidic channel is much deeper than the molecules, they can't be separated. As the channel becomes shallower, separation improves. That's because, in a channel that is much shallower than the hydrodynamic radii of the molecules, the molecules have to stretch and contort to wend their way through.

Another area in which Ramsey is using nanofluidics is ion concentration. He and postdoc Nickolaj Petersen use the junctions of micro- and nanoscale channels to deplete or concentrate ions, depending on the magnitude and polarity of the electrical potential applied to the system. Ramsey also considers the work being done with nanopores to be a branch of the emerging science of nanofluidics and an area that could be scientifically and technologically fertile.

Fundamental questions remain about nanofluidics, Ramsey said. Much is still unknown about the properties of fluids confined at that scale. Also, the best method for fabricating such devices is yet to be determined. Should they be fabricated from the top down by etching channels into devices, or should they be built from the bottom up by adding one molecule or atom at a time? Either way, atomic-level control of fabrication is necessary.

These are still the early days for nanofluidic research. Riffing on Richard Feynman's famous quote about nanotechnology, Ramsey said: "There's still lots of room at the bottom of nanofluidics."

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter