Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Catalytic two-step for better diesel

April 17, 2006

| A version of this story appeared in

Volume 84, Issue 16

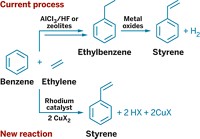

With petroleum prices soaring, an 80-year-old process that can convert carbon sources like coal and biomass into liquid fuel is taking on a new luster. One reason the Fischer-Tropsch (F-T) diesel-making process hasn't taken off globally is that it yields a complex hydrocarbon brew. A portion of it consists of the fuel "sweet spot:" alkanes in the C9 to C20 range. It takes refining steps to either remove or rework the components that are smaller and larger than those in that range. Alan S. Goldman of Rutgers University, Maurice Brookhart of the University of North Carolina, Chapel Hill, and coworkers have devised a two-catalyst approach that might help (Science 2006, 312, 258). One catalyst dehydrogenates alkanes, such as hexane, into alkenes. The second catalyst orchestrates metathesis reactions involving the alkenes. Hydrogenation with the first catalyst gives longer, fuel-friendly alkanes. "This could ultimately make the overall process more economical," Goldman says. Charles Benham of Rentech, a Denver-based firm working toward commercial F-T diesel production, has seen plenty of good ideas, but catalyst cost and stability are frequent showstoppers, he says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter