Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Happening Hafnium

Once obscure transition metal is now garnering attention as a potential superstar catalyst

by Stephen K. Ritter

October 8, 2007

| A version of this story appeared in

Volume 85, Issue 41

TITANIUM AND ZIRCONIUM have traditionally dominated group 4 chemistry. Hafnium, the third member of this group of early transition metals, has been the odd element out. But not anymore.

Steady progress in revealing hafnium's secrets during the past decade, including several key findings made this year, has the chemistry community taking notice of hafnium's potential capabilities as a catalyst to advance N2 and C–H activation reactions.

Christoph Marschner, a chemistry professor at Graz University of Technology, in Austria, describes hafnium's foray "into the limelight" in a recent commentary (Angew. Chem. Int. Ed. 2007, 46, 6770). As an element, hafnium is a latecomer to the periodic table, Marschner writes. Titanium and zirconium were discovered in the late 1700s, but hafnium was not proven to exist until 1923. Marschner chalks up the belated discovery to the close resemblance between hafnium and zirconium. The metals are nearly identical in their physical and chemical properties, and hafnium accompanies zirconium in its minerals.

"If the chemistry of hafnium and zirconium are compared, it seems that the heavier hafnium, similar to the situation with the siblings palladium and platinum, imitates zirconium in a sluggish way," Marschner observes. For this reason, chemists have taken a while to uncover the subtle differences that can be exploited between titanium, zirconium, and hafnium. One of these differences, stemming from hafnium having a layer of f electrons in its electronic structure, is that hafnium participates more strongly in σ bonding with ligands, Marschner explains. This property endows hafnium with a slight edge in mediating certain types of chemical reactions.

Converting N2 directly into value-added chemicals such as amines or heterocycles could be one of them, write Michael D. Fryzuk of the University of British Columbia and Yasuhiro Ohki of Nagoya University, in Japan, in another commentary about hafnium (Angew. Chem. Int. Ed. 2007, 46, 3180). Such conversions could circumvent the energy-intensive Haber-Bosch process, a long-sought goal for the chemical industry. This workhorse reaction, requiring heat, pressure, and a heterogeneous iron catalyst, converts N2 to ammonia, which is used to make nitrogen-containing compounds. So far, a homogeneous catalytic process run under mild conditions for this reaction remains elusive, despite dozens of known transition-metal N2 complexes as starting points, they note.

ONE RECENT EXAMPLE of hafnium-based N2 activation that has chemists abuzz comes from Cornell University's Paul J. Chirik and coworkers. Chirik's group has shown that group 4 metallocenes—complexes in which the metal is sandwiched between cyclopentadienyl ligands—can be coaxed to preferentially bind N2. Dinitrogen generally is not a good ligand, but it can coordinate to transition metals in several ways, including end-on to one metal, side-on bridging two metals, or a combination of those two modes. Chirik's complexes bind N2 side-on between the metal atoms of two metallocene molecules.

The usually tight N≡N bond is a little longer and weaker in the coordinated side-on complexes, giving the bound N2 some imido-like qualities. This bonding interaction opens N2 to attack and functionalization by electrophiles such as H2 and hydrocarbons.

Chirik and coworkers reported last year that hafnocene-N2 and zirconocene-N2 complexes react with H2 to form a hydrazine core, N2H4, between two metallocene units. These complexes release small amounts of ammonia, suggesting that they are facilitating the desired N2 reduction to ammonia. The reactions aren't catalytic, but Chirik's group has shown that the hafnium complex reacts about four times faster than the zirconium complex. Chirik recently reviewed his group's work in this area, including discussing plausible reaction mechanisms, in a perspectives article (Dalton Trans. 2007, 16).

"It is remarkable that the only dinitrogen complexes to date that result in N–H bond formation by reaction with H2 are systems based on group 4 metals," Fryzuk and Ohki write. And although hafnium has been a less frequent participant in N2 activation because it's the most difficult group 4 metal to reduce, it offers a broader range of reactivity patterns compared with zirconium, they add.

An example of hafnium's broader reactivity is Chirik's demonstration that reaction of the dihafnocene-N2 complex with CO2 leads to double insertion of CO2 into the Hf–N bonds to form a N2-CO2 core (Angew. Chem. Int. Ed. 2007, 46, 2858). Addition of Me3SiI (Me = methyl) to the compound liberates N2-CO2 by forming the stable dicarboxyl hydrazine (Me3Si)2N–N(CO2SiMe3)2 mixed with iodinated hafnocene, which can be recycled.

It's not so much that hafnium is more reactive than zirconium or titanium, Chirik notes, but that it's more reducing, which means hafnium will do whatever it can to stay in the higher Hf(IV) oxidation state, including forming unusual complexes. "That's why, in part, our chemistry works," Chirik says.

Fryzuk and Ohki point out that Chirik's reactions have expanded the kinds of transformations possible with coordinated N2. Although chemists aren't much closer to developing the highly sought catalytic cycles involving N2, they add, "optimism for further advances in N2 functionalization remains."

In other hafnium chemistry, Uwe Rosenthal of the Leibniz Institute for Catalyisis at the University of Rostock , in Germany, and coworkers have shown that the metal can mediate never-before-seen Si–C and C–H activation reactions.

Rosenthal's team has been exploring group 4 metallocene reactions with acetylenes for several years. The group quickly met success in forming adducts between bis(trimethylsilyl)acetylene (Me3SiC≡CSiMe3) and titanocene and zirconocene. The C≡C bond coordinates side-on with the metal to form a three-membered ring, with each carbon retaining a trimethylsilyl substituent. But for hafnium, the research team ran into a wall when the adduct failed to form under the same reaction conditions.

BY TWEAKING the reactants to include a different reducing agent in a more inert solvent, Rosenthal's group finally produced the hafnium adduct (Organometallics 2007, 26, 247 and 3000). In doing so, the team made an interesting discovery of an alternative reaction pathway to a side product. This reaction, not observed for titanium or zirconium, has added to the growing interest in hafnium.

Besides forming the expected acetylene adduct, reaction of decamethylhafnocene with Me3SiC≡CSiMe3 leads to unprecedented tandem Si–C and C–H activation reactions (Angew. Chem. Int. Ed. 2007, 46, 6907). As Rosenthal describes it, the side reaction proceeds via addition of the hafnocene across one of the Si–C bonds of the acetylene. The intermediate formed rearranges to a linear vinylidene complex bound end-on to hafnium, which stabilizes itself by addition of the hafnium center into a C–H bond of a methyl group of one of the cyclopentadienyl rings. The result is an unusual bridging Hf–C bond. A similar bridging-type bond has been observed by Chirik's group for hafnocene-N2 intermediates.

This compound further reacts via a second C–H activation, this time with a trimethylsilyl group, to form a stable five-membered ring—a hafnasilacyclopentene. Calculations by Rosenthal's longtime collaborators on group 4 chemistry, Eluvathingal D. Jemmis and his group at the Indian Institute of Science, in Bangalore, India, predict the kinetics and thermodynamics of the reactions and support the proposed mechanism.

"This enhanced reactivity of hafnium organometallic compounds should always be considered if syntheses are investigated or applied catalytically," Rosenthal says. Elaborations on the hafnium chemistry to produce other metallocyclic products are under way in his lab, he says.

Yet another recent report on hafnium chemistry comes from a team at Dow Chemical. The researchers describe an advance in the unique "chain-shuttling polymerization" process they developed for continuous production of tailored olefin block copolymers (C&EN, May 8, 2006, page 9). Rather than using a single reactor and two catalysts with substantially different monomer selectivities as in the original process, the team has now demonstrated that it can use just a single hafnium catalyst and two reactors containing different monomers in succession in a continuous process to make diblock copolymers (Macromolecules 2007, 40, 7061).

"This dual-reactor scheme produces a very different material than our single-reactor process," says Dow's Phillip D. Hustad, a researcher at the company's Freeport, Texas, site. Rather than giving a multiblock polymer chain architecture, the polymerization results in chains containing just two blocks.

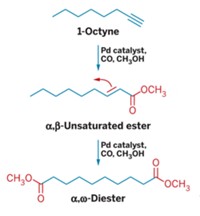

In the original process, the researchers used high-throughput screening to identify potentially useful polyolefin catalysts. They found a zirconium bis(phenoxyimine) catalyst selective for ethylene and a hafnium pyridylamide catalyst highly reactive with 1-octene. The catalysts have bulky ligand systems that restrict access to the metal centers, similar to metallocene catalysts typically used for commercial production of olefin homopolymers and random copolymers.

The chain-shuttling polymerization employs diethylzinc as the chain-transfer reagent. Diethylzinc typically is used to terminate polymer chain growth by transferring the polyolefin chain from the catalyst metal to zinc in exchange for an ethyl group. Usually irreversible, this process has been shown to be reversible in some cases. The Dow researchers take advantage of this reversibility to use the zinc reagent as a reservoir to hold polymer chains as they are intermittently shuttled between the different catalyst molecules to grow alternating ethylene-octene polymer blocks.

The Dow process has many advantages, the researchers say. For example, it leads to a better quality polymer than random copolymers or two polymers that are physically blended, and it does so in a more efficient, economical, and potentially greener way than current commercial copolymer batch production processes. The polymers have a useful combination of high-melting-point, "hard" crystalline segments with low octene content and low-glass-transition-temperature, "soft" amorphous segments with higher octene content.

To demonstrate the extended technology, the Dow chemists prepared a copolymer with blocks of high-density polyethylene and very-low-density polyethylene. They used the same hafnium pyridylamide catalyst as in the original system. Typically, block copolymers are made one chain at a time by sequentially adding one monomer and then another to a single reactor. In the new process, several polymer chains are produced simultaneously in the first tank reactor, assisted by diethylzinc. The effluent from the first reactor flows into a second reactor, where the second copolymer blocks are added.

Overall, this continuous process ensures a homogeneous copolymer composition within each block "in sharp contrast to materials produced in batch or semibatch processes," Hustad notes.

On the basis of all these recent studies on hafnium, "a new player has entered the stage of transition-metal chemistry," Marschner writes. "Hafnium is on track to lose its image as a pale 'zirconium clone.' " Although the examples witnessed so far are mostly stoichiometric, possible catalytic properties connected to the work are "eagerly anticipated," he adds.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter