Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Beefy Carbon Nanotube Fibers

November 19, 2007

| A version of this story appeared in

Volume 85, Issue 47

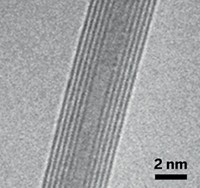

Individual carbon nanotubes are prized for their strength and stiffness, and scientists have been thinking that those properties might translate into high-performance fibers made from the material. In 2004, Alan H. Windle and coworkers at the University of Cambridge reported the fabrication of such fibers using a one-step process that employs a rotating rod to mechanically draw the fibers from a nanotube aerogel. Windle's group has now characterized those fibers and found that their strength, stiffness, and toughness are roughly twice those of DuPont's Kevlar aramid fiber, one of the toughest materials known (Science, DOI: 10.1126/science.1147635). The fibers are primarily composed of double-walled carbon nanotubes with a diameter of 4-10 nm. This relatively large diameter causes the tubes to collapse upon themselves, Windle explains, thereby maximizing the contact area between tubes. Nanotubes in the fibers measure approximately 1 mm in length. Windle notes that this high aspect ratio gives the tubes good mechanical and stress transfer properties. Next, Windle's group hopes to scale up the process for commercial production.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter