Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Analyzing Batteries One Slice At A Time

Method enables lithium-ion battery defects to be probed by transmission electron microscopy

by Mitch Jacoby

March 19, 2008

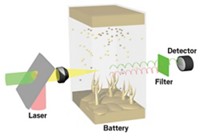

Researchers in France and Japan have demonstrated a procedure for preparing nanometer-thick cross sections of solid-state lithium-ion batteries and analyzing the thin slices in a transmission electron microscope (Chem. Mater., DOI: 10.1021/cm7033933).

The first-of-its-kind study revealed structural defects within the batteries' layers. It also showed that interfaces that are initially pristine in unused batteries deteriorate upon charging and discharging as minute quantities of cobalt, vanadium, silicon, and other materials migrate from one battery component and contaminate adjacent ones. That type of information may ultimately lead to improved performance and longevity for rechargeable batteries that are used in cell phones and laptops.

Loic Dupont and Adrien Brazier at the University of Picardie Jules Verne, in France, and coworkers there and at Tohoku University, in Japan, fabricated multilayered thin-film batteries consisting of a LiCoO2 cathode, a Li-V-Si-based solid electrolyte layer, a SnO anode, and other components. The researchers used a focused ion beam to cut battery slices less than 100-nm thick and analyzed the specimens' physical structure and chemical composition with nanoscale resolution.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter