Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Catalyst Active Site Revealed

An Al–O–Mo linkage is the active species in a molybdenum-based zeolite catalyst that converts methane to benzene

by Mitch Jacoby

March 11, 2008

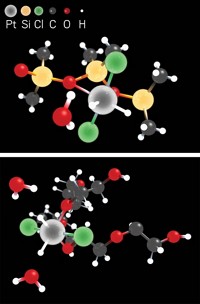

By coupling materials synthesis and catalytic-activity studies with a powerful NMR spectroscopy method, a team of researchers at Pacific Northwest National Laboratory, in Richland, Wash., and the Dalian Institute of Chemical Physics in China has identified the active species in a molybdenum-based zeolite (aluminosilicate) catalyst that converts methane to benzene. It is an aluminum-oxygen-molybdenum linkage (J. Am. Chem. Soc., DOI: 10.1021/ja7110916). The study could lead to efficient methods for transforming methane into more valuable and easily transported liquids, which in turn could provide the chemical industry with incentives to tap supplies of natural gas in remote areas.

To boost ordinarily weak Mo NMR signals, Heng Zheng, Xinhe Bao, and coworkers prepared a series of catalysts from a 95Mo-enriched precursor material, evaluated the materials' catalytic activities, and used an ultra high-field NMR method to probe the samples. On the basis of those measurements, the team concluded that during catalyst preparation molybdenum atoms migrate into the zeolite channels and anchor onto acidic aluminum sites, thereby forming Al???O???Mo linkages. These structures serve as catalytically active centers in the methane-conversion reactions.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter