Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Porous Carbon/Metal Oxide Microfibers

New strategy to create hollow fibers uses ice and silica particles

by Rachel Petkewich

April 2, 2008

With a "brick and mortar" assembly approach, researchers have made porous, hollow carbon/metal oxide microfibers with well-controlled pore structures (J. Am. Chem. Soc., DOI: 10.1021/ja800376t).

Composites of carbon and metal oxide are useful for catalysis, electrochemistry, and electro-optical applications. Although existing techniques can already yield uniform pore structure in carbon fibers, materials researchers say precise control over the formation of uniform pores in carbon/metal oxide fibers has remained challenging.

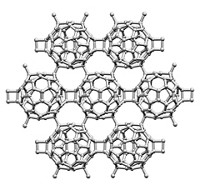

In the new study, chemistry professor Galen D. Stucky and graduate student Qihui Shi at the University of California, Santa Barbara, and colleagues created "bricks" by coating silica spheres first with a metal oxide that contains, for example, zirconium or titanium and then with polyacrylonitrile. The spheres were dispersed into an aqueous polyvinyl alcohol (PVA) solution and frozen. With PVA acting as mortar, the spheres formed fibers when the ice was sublimed by freeze-drying. The researchers then pyrolyzed the resulting fibers. Dissolving the silica cores with a basic solution finally produced porous, hollow composite fibers. Silica particles and ice crystals both have been used as templates to form hollow fibers but not in combination.

Stucky says this clean, economic, and versatile large-scale synthetic method is suitable for assembling different core/shell-structured particles into a single fiber, giving the fiber multiple functionalities, such as catalytic or magnetic properties.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter