Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Graphene Via Self-Assembly

Preparation method uses mild conditions to make single-layer products

by Mitch Jacoby

July 8, 2009

By using a surfactant that serves as a structure-directing agent and a source of carbon, researchers in China have developed a synthesis method for producing graphene—a single layer of carbon atoms. The method yields purer products, is more reproducible, and offers additional advantages relative to other ways of making this ultrathin form of carbon (Angew. Chem. Int. Ed., DOI: 10.1002/anie.200902365).

Owing to its outstanding electronic, mechanical, and structural properties, graphene holds promise as a key component in various applications, including nanoelectronic devices and supercapacitors. As a result, researchers have developed a number of "top down" preparation methods based on peeling apart sheets of graphene from bulk graphite and high-temperature treatment of silicon carbide.

Weixia Zhang and Guangtao Li of Tsinghua University, in Beijing, and coworkers now demonstrate a "bottom up" synthesis that proceeds under mild conditions and yields gram-scale quantities of pure single-layer graphene.

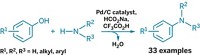

By reacting a lysine-based surfactant bearing a terminal pyrrole moiety with tetraethoxysilane, the team exploits a self-assembly process that packs the pyrrole units into a confined layer between sheets of silica. They then polymerize the pyrrole and heat the intermediate product to convert the organic component to a single layer of carbon. Finally, they remove the silica sheets with dilute acid to yield single-layer graphene.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter