Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Merck KGaA Leads OLED Consortium

Illuminating Technology: German alliance will develop soluble materials for lighting applications

by Michael McCoy

November 3, 2009

Merck KGaA is leading a new German consortium that aims to develop soluble materials to be used in large organic light-emitting diodes (OLEDs) for applications such as televisions and lighting systems.

Composed of 11 partners, four from industry and seven from academia, the consortium has a budget of more than $45 million. Half of it will come from the Germany Federal Ministry of Education & Research; the industrial partners will contribute the rest.

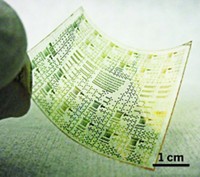

Today, OLEDs created with vacuum evaporation technology find use in small displays for cell phones and MP3 players. The consortium wants to develop soluble phosphorescent materials that can facilitate the manufacturing of much larger displays.

"OLEDs have tremendous future potential as a cost- and energy-efficient lighting technology," says Udo Heider, vice president of Merck's OLED business. "We want to provide industry with customized OLED materials, thus enabling cost-effective manufacturing processes from the liquid phase."

Merck's contribution to the consortium is the development and testing of new light-emitting systems based on soluble small molecules. Among other participants, H.C. Starck, for example, is working on conductive polymer anode materials that could replace expensive indium-tin oxide anodes.

Merck is already involved in a similar consortium backed by the German government. This summer the company said it would head a group developing raw materials and manufacturing processes for printed organic circuits with integrated sensors (C&EN, July 6, page 14).

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter