Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Porous Balancing Act

Zeolites: Method forms large pores without sacrificing small ones

by Mitch Jacoby

November 19, 2009

Treating zeolites with alkaline solution and relatively large organic cations endows the porous crystals with a custom distribution of pore sizes ideally suited to catalytic applications, according to researchers in Spain (Adv. Funct. Mater., DOI: 10.1002/adfm.200901394).

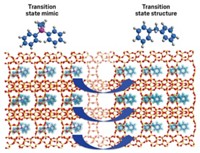

Zeolites are porous crystalline aluminosilicates that are widely used as catalysts in petroleum refining. For years, scientists have sought ways to prepare zeolites with large pores (mesopores, with multinanometer diameters) to better accommodate large molecules and enhance the flow of reactants and products in and out of the crystals. Several methods have been developed, but many form large pores by eliminating naturally occurring smaller ones (micropores), which are often the location of catalytically active sites and hence critical to catalytic performance.

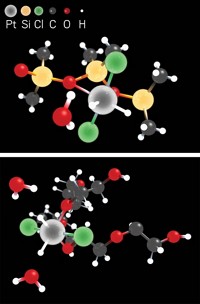

Now, a team led by Javier Pérez-Ramírez at Catalonia Institute of Chemical Research, in Spain, reports that treating zeolite ZSM-5 with sodium hydroxide in the presence of tetrapropyl- or tetrabutylammonium ions (TPA+ and TBA+, respectively) enhances the dimensions of the large pores without unduly sacrificing the smaller ones.

The team, which includes chemists Danny Verboekend, Adriana Bonilla, and Sònia Abelló, explains that hydroxide ions leach silicon from the micropore interiors, thereby enlarging pores. But pore growth, which until now has been difficult to control, is moderated by the relatively large cations TPA+ and TBA+, which adsorb at the pore entrance and impede hydroxide leaching. Smaller ions do not moderate pore growth, they say.

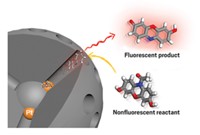

To quantify the catalysis benefits of the new method, the Catalonia group compared zeolites made in various ways by a parameter they developed: hierarchy factor (HF), or the product of relative micropore volume and mesopore surface area. In test reactions, the team found that the most productive catalysts were zeolites with the largest HF values.

HF appears to be a useful parameter for gauging catalytic performance in zeolites, says Claus H. Christensen, a zeolite specialist at Haldor Topsøe in Denmark. He notes that the study is an "important development" that points to a novel way of maximizing zeolites' catalytic potential.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter