Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Multifunctional Membranes

Chemists engineer multicomponent block polymers to serve as nanoporous filtration membranes

by Stephen K. Ritter

January 3, 2011

| A version of this story appeared in

Volume 89, Issue 1

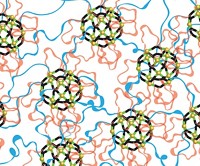

Marc A. Hillmyer of the University of Minnesota, Twin Cities, unveiled his group’s “reaction-induced self-assembly method” as a modular approach for engineering multifunctional, multicomponent block polymers to serve as nanoporous membranes for drug delivery, water filtration, and separations applications. In commercially available ultrafiltration membranes, there’s a trade-off between membrane selectivity and liquid permeability—highly selective membranes have low permeability and vice versa, Hillmyer explained. To overcome this problem, Hillmyer’s group has been using the new method to prepare membranes that combine high porosity and narrow pore-size distributions with tunable chemical and mechanical properties. In one example, Hillmyer and coworkers made a membrane from a polymer containing a reactive polystyrene copolymer block (blue), a poly(N-isopropylacrylamide) block (PNIPAM, red), and a poly(lactide) block (PLA, green). In the presence of a metathesis catalyst, the reactive block cross-links with polymerizing dicyclopentadiene (blue diamonds) to create the membrane matrix. Etching out the PLA creates pores lined with thermally responsive and reactive PNIPAM. The resulting tough nanoporous material can be formed as thin sheets and holds potential as a highly selective, highly permeable water-filtration membrane, Hillmyer said.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter