Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Key Catalyst Support Parameters Identified

Maximum surface area coupled with 3D interconnectivity enhances catalytic activity and selectivity

by Mitch Jacoby

May 30, 2011

| A version of this story appeared in

Volume 89, Issue 22

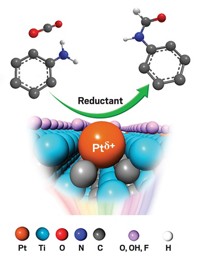

By conducting a detailed comparison of silica materials used as palladium-catalyst supports, researchers in the U.K. have uncovered key criteria that make some supports far superior to others in selective alcohol oxidations. The team also identified the catalytically active species that mediate conversion of allylic alcohols to the corresponding aldehydes, an industrially significant process (ACS Catal., DOI: 10.1021/cs200145n). Christopher M. A. Parlett, Adam F. Lee, and Karen Wilson of Cardiff University, Wales, and coworkers in England prepared palladium catalysts on four types of silica that widely vary in pore architectures and surface areas (200–950 m2/g). Through a series of microscopy, spectroscopy, and other types of measurements that probed the catalysts and monitored formation of cinnamaldehyde and separately crotonaldehyde, the team found that the best supports feature the highest surface areas and a three-dimensional network of interconnected channels. Some high-surface-area silicas lack 3-D interconnectivity, which is needed for maximizing palladium dispersion and enhancing mass transport, the group says. Additionally, they found that Pd2+ species (PdO) are responsible for the rate-limiting oxidative dehydrogenation step.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter