Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biological Chemistry

Combo Method Yields Chondroitin Sulfate

A microbiological-chemical approach is the first prep-scale synthesis of the naturally sourced osteoarthritis drug

by Stephen K. Ritter

June 6, 2011

| A version of this story appeared in

Volume 89, Issue 23

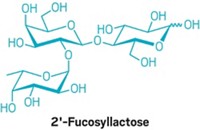

By coupling microbiological and chemical techniques, Emiliano Bedini of the University of Naples Frederico II, in Italy, and coworkers have developed the first preparative-scale synthesis of the pharmacological version of chondroitin sulfate, a compound widely used to treat osteoarthritis (Angew. Chem. Int. Ed., DOI: 10.1002/anie.201101142). Chondroitin sulfate is a glycosaminoglycan polysaccharide variously substituted with sulfate groups that serves as a key structural component of cartilage. It’s popular as a dietary supplement in the U.S. and used as a prescription drug in Europe and elsewhere to improve joint health. The compound is currently sourced from cow, pig, and shark cartilage, but the low abundance of the raw material, its laborious purification, and the potential for disease transmission from animals have sparked efforts for a synthetic source. Using a fermentation process, Bedini’s team employed a strain of Escherichia coli known to produce a chondroitin-based polysaccharide, then added an enzyme to remove a fructose group to obtain pure chondroitin. They subsequently used pyridine-sulfur trioxide in a multistep procedure to selectively add sulfate groups to produce gram amounts of chondroitin sulfate with the requisite sulfation pattern (shown). The high-yield, low-cost synthesis could become the method of choice for chondroitin sulfate production, Bedini believes.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter