Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

Zeolites Don’t Mind Hot Water

Catalysis: Organosilyl groups stabilize workhorse catalysts for aqueous-phase reactions

by Stephen K. Ritter

May 14, 2012

| A version of this story appeared in

Volume 90, Issue 20

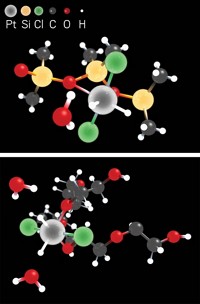

Tacking hydrophobic organosilyl groups onto the surface of a common zeolite helps overcome the catalyst’s inability to function effectively when liquid water is the reaction medium, chemical engineers have found. The researchers believe their water-repelling zeolite could be a hit for high-pressure water/oil emulsion processing of biomass into fuels and chemicals. The protecting group strategy could also benefit other types of catalysts that are inhibited by water, they say.

Zeolites are aluminosilicate materials with reactive acidic sites and are widely used in vapor-phase refinery processes. They have a low tolerance for hot liquid water, however, which causes them to lose their crystallinity and catalytic activity.

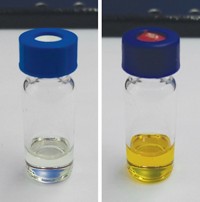

Paula A. Zapata, Jimmy Faria, Daniel E. Resasco, and coworkers of the University of Oklahoma, Norman, reasoned that studding a zeolite’s external surface with hydrophobic octadecylsilyl groups would hinder diffusion of water into the zeolite’s pores and prevent the collapse of the framework structure (J. Am. Chem. Soc., DOI: 10.1021/ja3015082). They found by an assortment of X-ray, spectroscopy, and microscopy methods that untreated HY zeolites begin to fall apart within a few hours at 200 °C in aqueous reactions, whereas their functionalized HY zeolite retains its crystallinity, surface area, porosity, and density of reactive acidic sites under the same conditions.

The Oklahoma researchers tested the catalysts in common biorefinery reactions, such as dehydration of 3-pentanol to pentene and 2-propanol to propylene, as well as alkylation of m-cresol with 2-propanol. The functionalized zeolite outperformed unfunctionalized zeolites in product yield. It also was better in stabilizing the water/decalin biphasic reaction medium, which helps separate the products and recycle the catalyst.

The new zeolite “could represent a big step for biomass conversion,” says George W. Huber of the University of Massachusetts, Amherst, an authority in biomass processing.

“Aqueous media is a great way to convert biomass into fuels and chemicals, because most biomass components are water soluble,” Huber notes. The Oklahoma team’s results “now suggest a way to modify zeolites so they can be used in water,” Huber says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter