Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Functionalized Graphene Nanoballs

Simple method crumples graphene flakes and coats them with metal or metal oxide nanocrystals

by Mitch Jacoby

August 13, 2012

| A version of this story appeared in

Volume 90, Issue 33

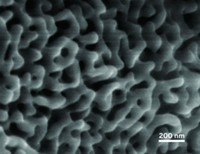

A one-pot procedure converts solutions of graphene oxide and precursor ions to crumpled sheets of graphene decorated with nanocrystals, according to a study led by researchers at the University of Wisconsin, Milwaukee (ACS Nano, DOI: 10.1021/nn302818j). The method builds on work reported recently by other scientists that shows graphene sheets can be crumpled into nanosized balls that resist uncrumpling, aggregating, and stacking. The wadded-up form of carbon is endowed with high surface area, making it attractive for energy storage and other applications. But access to those applications typically requires additional chemical processing steps. UW Milwaukee’s Shun Mao and Junhong Chen and coworkers created a general method for making graphene nanoballs and functionalizing them with metals or metal oxides in a single step. The team reports that flowing aerosols of graphene oxide suspensions containing nanoparticle precursors through a furnace causes the aerosol droplets to rapidly evaporate. That process crumples and partially reduces the carbon flakes and triggers spontaneous growth of nanocrystals on the inner and outer surfaces of the balls. The researchers made supercapacitors and lithium-ion batteries from nanoballs coated with Mn3O4 and SnO2, respectively, and report that the devices outperform versions made from flat graphene sheets.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter