Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Xylene From Ethylene

Chemists create process to make terephthalic acid precursor from alternative feedstocks

by Stephen K. Ritter

October 1, 2012

| A version of this story appeared in

Volume 90, Issue 40

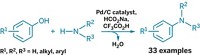

Chemists have invented a method to selectively prepare p-xylene from only ethylene (J. Am. Chem. Soc., DOI: 10.1021/ja307612b). The achievement creates an opportunity to make the commodity chemical terephthalic acid and its blockbuster derivative polyethylene terephthalate (PET) from alternatively sourced p-xylene. p-Xylene is typically produced by catalytic reforming of various crude oil streams in refineries. Using ethanol from biomass or ethane from shale gas would reduce reliance on crude oil as feedstock for p-xylene production. The process, developed by Thomas W. Lyons, Maurice Brookhart, and coworkers at the University of North Carolina, Chapel Hill, starts with chromium-catalyzed ethylene trimerization to form hexene, followed by an iridium-catalyzed dehydrogenation step to make hexadiene. The researchers then couple hexadiene with more ethylene in a Diels-Alder cycloaddition reaction to form 3,6-dimethylcyclohexene. Subsequent dehydrogenation using a platinum catalyst converts 3,6-dimethylcyclohexene to pure p-xylene. Making PET requires costly purification technologies to separate p-xylene from a mixture of benzene, toluene, and o-, m-, and p-xylene. The new synthesis avoids that problem.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter