Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Next Generation: NIST Researchers See Promise In Clay-Based Nanomaterial Coatings

by Cheryl Hogue

October 29, 2012

| A version of this story appeared in

Volume 90, Issue 44

\

\

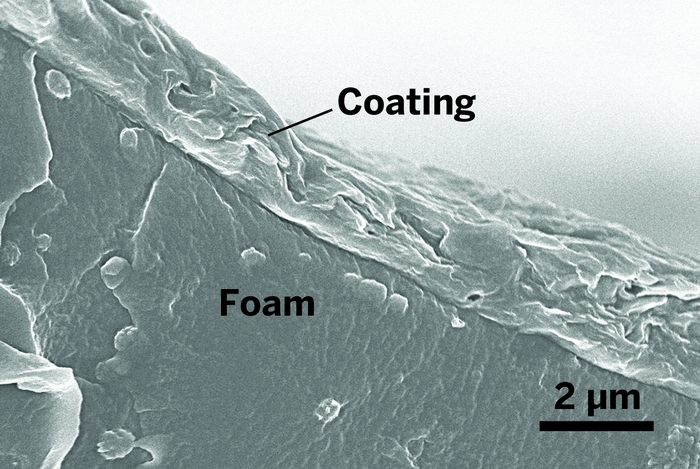

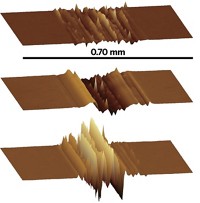

The clay-based nanomaterial coating, shown in a scanning electron microscope image (bottom), is assembled layer by layer atop polyurethane foam. When the treated foam is exposed to an open flame, the coating forms a protective char (top).

While policy debates over fire- safety standards and flame retardants rage on, researchers at the National Institute of Standards & Technology are developing new types of fire-blocking technology.

One promising effort at NIST is aimed at reducing the flammability of polyurethane foams, such as those used to pad furniture, by coating them layer by layer with a polymer-embedded, clay-based nanomaterial. When constructed, this layered coating, ranging in thickness from a few hundred nanometers to 1 µm, serves as fire-blocking armor.

“In effect, we can build the equivalent of a flame-retarding clay wall on the foam,” says Rick D. Davis, leader of the Flammability Reduction Group at the institute’s Engineering Laboratory. Davis and colleagues Yeon Seok Kim and Richard Harris describe this work in a study published in ACS Macro Letters in June (DOI: 10.1021/mz300102h).

COVER STORY

Next Generation: NIST Researchers See Promise In Clay-Based Nanomaterial Coatings

Nanomaterial-coated foams could eventually become an alternative to foams treated with flame-retardant chemicals, Davis tells C&EN. “Our clay-based coatings perform at least as well as commercial flame retardants,” he says. Studies at NIST have found that clay-based coatings can cut the flammability of the foam by 40% when compared with untreated foam. In contrast, fire-retardant chemicals added to foam reduce its flammability by 10 to 30%, Davis says.

Researchers at NIST have experimented with a variety of nanomaterials, Davis says. They include cellulosic nanofibers, multiwalled carbon nanotubes, and ionic fire retardants such as sodium phosphates. In tests, the clay-based coatings showed the best flammability reduction, so NIST efforts are focusing on them, Davis says.

The clay nanoparticles used in NIST’s experiments are embedded in a polymer matrix to reduce the chance that they will escape into the environment, Davis continues. In experiments that simulate years of wear on furniture, the nanomaterials stayed in the coatings, Davis says. “They don’t come out.” The nanomaterials’ persistence on the materials they are applied to means that their flame-retardant properties will remain strong despite years of use, Davis says. He adds that scientists at Duke University are conducting toxicity testing of the nanomaterials NIST has used in these ignition-resistant coatings.

In contrast, some fire-retardant chemicals widely used in foams can migrate into household dust and are found in people and wildlife, according to published studies. Toxicity data for many of these compounds are scarce.

Nanoparticle coatings, in addition to lowering flammability, make the foam easier to clean, more resistant to breakdown from ultraviolet light, and better able to withstand weather, Davis says.

The nanoparticle and polymer coatings boost the mass of a foam by 5 to 10% and can make it slightly stiffer than uncoated foam, Davis says. Flame-retardant chemicals also increase the mass of foam by 5 to 25% and affect softness.

In addition to use on foams, the nanoparticle coatings hold promise for textiles, meaning they could find application in clothing, carpets, and draperies, Davis says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter