Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Nanoconfinement Prevents Nickel Catalyst From Fouling

Unconventional synthesis yields sheltered nanoparticles that stand up well to harsh reaction conditions

by Mitch Jacoby

November 12, 2012

| A version of this story appeared in

Volume 90, Issue 46

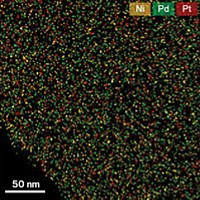

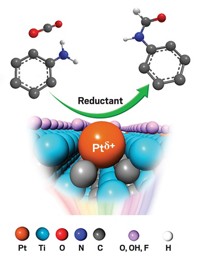

By confining small particles of nickel in the pores of a zirconium dioxide matrix, researchers in China have developed a long-lasting and active catalyst that resists common routes to fouling and deactivation (Chem. Commun., DOI: 10.1039/c2cc37109j). The study may lead to methods for preparing a variety of robust nanocomposite catalysts that tolerate high temperatures and high humidity. Nickel nanoparticles supported on metal oxides serve as catalysts for various types of hydrogenations and other reactions. The catalytically active and low-cost metal could be used more widely, but it’s prone to high-temperature deactivation via particle fusing (sintering) and carbon deposition (coking). Jinlong Gong and coworkers at Tianjin University devised a surfactant-assisted technique for preparing NiO nanoparticles and a hydrothermal method for reducing and confining the particles in a ZrO2 matrix. Compared with conventional methods for impregnating metals in oxides, the new method yields smaller particles with four times as much surface area. Furthermore, unlike standard supported nickel catalysts, the new ones resist sintering and coking, as determined from 50 hours of hydrogen production via steam reforming of ethanol. The researchers attribute the catalyst stability to the similarity in size of Ni and ZrO2 particles, which inhibits sintering, and high oxygen mobility in the matrix, which impedes coking.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter