Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Triple Protection For Nanoparticles

ACS Meeting News: Uniform coating prevents common catalyst deactivation mechanisms

by Mitch Jacoby

March 27, 2012

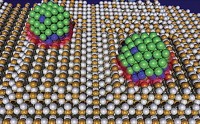

Applying a uniform oxide coating to metal nanoparticles used for catalytic hydrocarbon processing simultaneously protects the particles from three common deactivation processes that can lead to frequent chemical reactor shutdowns, according to a study conducted by researchers at Northwestern University and Argonne National Laboratory.

The findings, which may help avoid the costly chemical plant interruptions, were reported on March 26 at the American Chemical Society meeting in San Diego at a symposium organized by the Division of Catalysis Science & Technology. The work is also published in Science (DOI: 10.1126/science.1212906).

A number of chemical and physical processes can rob nanosized metal catalyst particles of their ability to mediate chemical reactions. In hydrocarbon catalysis, the two most common routes to deactivation for such particles are sintering—which causes the particles to agglomerate and fuse together, thereby reducing the surface area available for chemical reactions—and accumulation of coke, a carbonaceous layer that blocks reactants’ access to catalytically active sites. Nanoparticle catalysts are also often ruined by forces that leach the particles from their supports.

Numerous strategies have been devised to avoid these debilitating processes (or to reverse their performance-sapping effects). Yet none of these procedures simultaneously protect catalysts from sintering, coking, and leaching, while enabling the catalysts to maintain high activity in high-temperature applications.

Peter C. Stair, a Northwestern University chemistry professor who also holds an appointment at Argonne, reported that oxide coatings made via atomic layer deposition (ALD) can indeed provide that type of catalyst protection.

ALD is a vacuum deposition process in which sequentially pulsed precursors react to form one atomic layer of protective products per pulse sequence. The technique is renowned for forming highly conformal and uniform layers even on porous and irregularly shaped, long-and-narrow substrates (C&EN, Aug. 1, 2011, page 38).

The team, which also includes Junling Lu, Mayfair C. Kung, and Jeffrey W. Elam, grew an 8-nm ALD shell of alumina (45 atomic layers) on otherwise conventional supported-palladium nanoparticles and compared the coated particles with uncoated ones in catalysis tests. They found that when the catalysts were used for 1 hour to dehydrogenate ethane to ethylene in oxygen at 650 °C, the coated catalysts accumulated only 6% as much coke as the uncoated ones and maintained high activity and product selectivity. In contrast, uncoated catalysts stopped making products after just 30 minutes. In addition, microscopy analysis showed that under reaction conditions, uncoated particles quickly sintered and were leached from the support. Stair reported that the ALD-treated catalysts showed no morphology changes even after reaction at 675 °C for 28 hours.

ALD encapsulation not only minimizes sintering of the palladium but “remarkably leads to selective poisoning of the catalytic sites for undesired side reactions,” says Bruce C. Gates of the University of California, Davis. But given the high cost of ALD, he predicts researchers may find it challenging to design economical ways to create such uniform coatings.

C&EN Covers The ACS National Meeting

Want the scoop on the ACS meeting in San Diego? Check out C&EN Picks, a series of videos that spotlight sessions selected by C&EN staff. Reporters also fan out across the meeting to bring you news coverage. Find it all collected at C&EN’s meeting page, cenatacs.tumblr.com.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter