Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Cheap And Fast Way To Purify Metallofullerenes

Chemical Separations: Lewis acids could help researchers quickly separate metallofullerenes from fullerenes

by Olga Kuchment

June 5, 2012

Japanese researchers have developed a simple method to purify metallofullerenes in minutes (J. Am. Chem. Soc., DOI: 10.1021/ja3030627). The new technique could make the materials attractive for applications in medicine and electronics, the researchers say.

Metallofullerenes are fullerenes, or buckyballs such as C¬70, with metal atoms trapped inside the carbon cage. Based on the materials’ electronic properties, chemists have thought that metallofullerenes could be used as contrast agents for magnetic resonance imaging or as components of flexible solar cells. But separating fullerenes that hold a metal atom inside from those that don’t requires many cycles of purification using high-performance liquid chromatography. As a result of this costly and time-intensive process, the materials’ promise has largely gone unfulfilled, says Hisanori Shinohara of Nagoya University, in Japan.

Shinohara and his coworkers have found a much simpler separation process that doesn’t involve HPLC. They had read reports that Lewis acids prefer to bind to metal-holding buckyballs than to bind to empty ones (Inorg. Chem., DOI: 10.1021/ic9017147). Intrigued, the team decided to test the ability of six metal halides to purify 10 metallofullerenes, such as C82 containing a gadolinium atom.

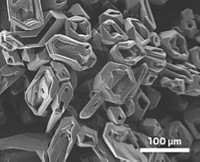

Titanium tetrachloride, which is a liquid at room temperature, worked the best by far. Minutes after the chemists added a few drops of TiCl4 to mixed solutions of metallofullerenes and metal-lacking fullerenes, a metallofullerene-TiCl4 complex precipitated out of the organic solvents. The scientists could easily remove the bound TiCl4 by washing the precipitate with water.

At the end of the process, which usually took less than 10 minutes, the metallofullerenes had purities greater than 99%, similar to the levels obtained by HPLC methods. The efficiency of the reaction depended on the oxidation potential of the metallofullerene: Materials with higher oxidation potentials were more difficult to purify.

Besides being faster, the TiCl4 purification method costs about 1/100 as much as HPLC methods, says Shinohara. The team has patented the process and hopes to work with a company to develop a commercial application.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter