Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Nanotube-Based Paint Measures Structural Strain

Nanomaterials: New coating could help engineers monitor the structural health of buildings and airplanes.

by Katherine Bourzac

June 22, 2012

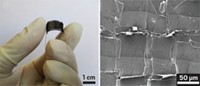

A coating made by mixing carbon nanotubes with commercial varnish could help engineers spot structural problems in buildings, bridges, and aircrafts before cracks and damage start to show (Nano Lett., DOI: 10.1021/nl301008m). After painting the mixture onto a structure, researchers can use an infrared spectrometer to measure the strain on the structure.

Monitoring structural integrity isn’t easy, says physical chemist R. Bruce Weisman of Rice University. Engineers can implant strain sensors into support structures, such as beams, when they’re manufactured. But the presence of these sensors can disrupt a structure’s integrity, so it’s not practical to use many, Weisman says. This method and others do not provide a finely detailed picture of the strain experienced over the whole structure.

Weisman and his colleagues developed a sensor-free means to map strain over an entire structure with a hand-held reader. They hope it will allow engineers to monitor strain more regularly and with greater detail than is possible with current methods.

They stumbled upon the method after studying the effects of strain on individual carbon nanotubes. In 2008, Weisman’s group demonstrated that when they stretched or compressed individual nanotubes, they changed the wavelengths of light that the tubes absorbed. The magnitude of this shift increased with the amount of strain put on the nanotube (Nano Lett., DOI: 10.1021/nl072861c). His Rice colleague Satish Nagarajaiah, a mechanical engineer, suggested that they could exploit this phenomenon to monitor structural strain.

The two set out to find the right material to mix with nanotubes to create a coating. Weisman says the resultant coating needed to meet several requirements: It had to be transparent; it had to be robust enough to stand up to sunlight, rain, and temperature changes; it couldn’t react with the nanotubes; and it had to prevent the nanotubes from clumping up, which would interfere with their stretching.

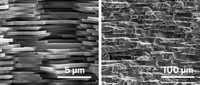

The Rice researchers found the ideal material at a hardware store: a urethane varnish formulated to protect wood from weathering. To make the strain-monitoring paint, the researchers mixed the varnish with single-walled carbon nanotubes at a concentration of 0.02% by weight.

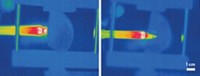

To test the coating, the scientists painted it onto a piece of Plexiglas. Once the coating was dry, the researchers attached a conventional strain sensor to the Plexiglas, and then clamped it to a bending jig mounted under a near-infrared spectrometer. As they bent the Plexiglas, they took simultaneous measurements from the spectrometer and the strain sensor. Even with small strains, such as deforming the Plexiglas from lying flat by just 0.04%, the researchers observed spectral shifts in the coating’s absorption spectra. Weisman and his team could measure strain on areas as small as 100 µm across, equal to the size of the spectrometer’s beam.

“To be able to detect such small strains with pretty high resolution is unique,” says materials scientist Paul Braun of the University of Illinois, Urbana-Champaign. Engineers, he adds, may be able to use this method to make a high-resolution strain map of the surface of a beam or an airplane wing—something that’s not possible today.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter