Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Researchers Build Compact Optical Circuit

Photonics: Circuit, which could find use in optical computers, integrates five lasers

by Katherine Bourzac

September 27, 2012

If computers calculated using light instead of electrons, they’d be more energy efficient and at least a thousand times faster than they are today. Unfortunately, the optical analogs of computer circuits are too bulky to vie with electronic ones. Now researchers have built a simple, micrometer-sized circuit that integrates five lasers (Nano Lett., DOI: 10.1021/nl302809a). Such a circuit could serve as the basis for future optical systems.

Researchers making compact optical circuits bump up against a fundamental physical limit: A light beam diffracts when it is narrower than half the wavelength of the light. This diffraction leads to weak signals in optical circuits. So, because of the diffraction limit, optical circuit components usually can’t be smaller than 1 µm—far larger than the 22-nm-wide transistors found in today’s electronic circuits.

Photonics researchers have found a way to get around the diffraction limit by transmitting light energy in the form of surface waves that travel along materials. These so-called plasmons have many of the same properties as photons but they don’t obey the diffraction limit, so plasmonic circuits can have a much smaller footprint.

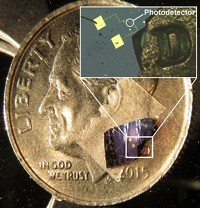

Xiang Zhang, of the University of California, Berkeley, his postdoctoral scholar Ren-Min Ma, and their colleagues built a source of plasmons that takes up an area of 0.48 µm2 on a silicon wafer. Other researchers have demonstrated these so-called plasmon lasers. But previous plasmon lasers have emitted in many directions, like a lamp does, says Ma. For plasmonic circuits to work, the plasmons have to move in a single direction, otherwise any signal contained in the plasmons will be weak and muddied. Also, researchers have yet to integrate these lasers with components necessary for optical circuits, such as waveguides to direct the plasmon beams and modulators to change the beams’ intensities. These changes in intensity would encode information in the plasmon streams, producing the circuits’ 1s and 0s.

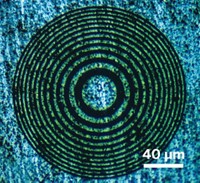

The Berkeley group came up with a design that solves these problems. They made their plasmon lasers by crossing perpendicularly two strips of material: a 800-nm-wide strip of silver and a 600-nm-wide strip of the semiconductor cadmium sulfide. Where the two materials meet, they’re separated by a thin layer of the insulator magnesium fluoride. When the scientists shine light from an external source, such as a standard laser, on this intersection of the two strips, the materials convert the energy in the light into plasmon waves. The CdS acts as a waveguide to direct the plasmons. And the silver strips serve as electrical contacts that allow the researchers to modulate the intensity of the plasmon beam.

The researchers made an array of five plasmon lasers of different colors on the same chip by crossing a single waveguide over five silver strips. The width of the waveguide at the intersection of the two strips dictated the laser color. They also demonstrated that the light from the plasmon lasers is highly directional: about 80% of the light flows in one direction, coupled to the waveguide.

Chih-Kang Shih, of the University of Texas, Austin, says this is the first demonstration of a plasmon laser that can be modulated. He says the next questions to answer are: “How fast can you modulate the laser, and can you make it even smaller?”

Ma says the group is working on several improvements to the device. For example, using laser light to produce the plasmons is not practical for an optical circuit. So the team is working on a design in which electricity from the silver contacts, rather than light, provides that necessary energy.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter