Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

Keeping A Watchful Eye On Biodiesel

ACS Meeting News: Optical sensor changes color in the presence of fatty acid methyl esters, serving as a tool for monitoring fuel quality

by Stephen K. Ritter

September 16, 2013

| A version of this story appeared in

Volume 91, Issue 37

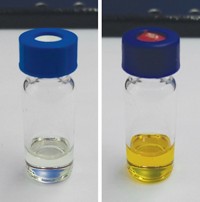

When it comes to airline safety, one technical detail most people don’t know about is the 5-ppm limit of biodiesel fuel contamination in jet fuel. This industry standard is needed because the fatty acid methyl esters derived from animal fat or vegetable oil that make up biodiesel have a higher freezing point than the alkanes in petroleum-derived fuels. Because different types of fuels are transported and stored with the same equipment, some biodiesel can end up in jet fuel and increase the viscosity of the fuel at the cold temperatures of high altitude, affecting engine performance or even causing an engine to stall. Current analytical techniques to test fuel quality often require costly and time-consuming off-site lab tests. Jonathan K. Fong and Zi-Ling (Ben) Xue at the University of Tennessee, Knoxville, have now devised a disposable optical sensor to signal unsafe biodiesel levels. The researchers dissolved the dye Nile blue chloride in methanol and then incorporated the mixture into an ethyl cellulose film made in ethanol. As the biodiesel methyl esters permeate the film, they displace the more polar alcohols, with the solvation difference causing the sensor to change color from blue to pink. The sensors the Tennessee team prepared detect biodiesel to 0.5 ppm concentration (Chem. Commun. 2013, DOI: 10.1039/c3cc43958e). By developing calibration curves and using a visible spectrometer, the fuel sensor could also be used by fuel distributors to verify the fraction of biodiesel blended with diesel, up to 200,000 ppm, or 20%. The University of Tennessee is patenting the sensor, Xue told C&EN.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter