Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Self-Healing Battery Anodes

Polymer coating gives long life to experimental high-capacity Li-ion batteries

by Mitch Jacoby

November 18, 2013

| A version of this story appeared in

Volume 91, Issue 46

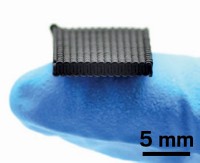

In the search for lithium-ion batteries with ever-higher charge capacity, researchers have found that replacing the typical graphite anodes with ones made of silicon could boost the batteries’ charge capacity, in principle, by a factor of 10. But with each charge-discharge cycle, the silicon swells and shrinks substantially, cracking the anode and quickly ending the battery’s life. Stanford University’s Chao Wang, Zhenan Bao, Yi Cui, and coworkers show that the cracking problem can be controlled by coating the anode with a stretchable self-healing polymer (Nat. Chem. 2013, DOI: 10.1038/nchem.1802). The team fashioned anodes from low-cost millimeter-sized silicon particles and coated them with a randomly branched hydrogen-bonding polymer. Analyses show that the polymer remains pliable and stretchable at room temperature, and its molecular chains readily reorient at fracture sites. As such, the polymer quickly repairs microsized cracks in the anode and maintains electrical contact among the silicon particles. The team reports that unlike earlier silicon-based Li-ion batteries, which barely survived 10 charge-discharge cycles, the new test batteries retained their charge capacities through 100 cycles.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter