Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Ultrasound Technique Creates Polymer Nanoparticles

Nanochemistry: Surfactant-free method could make nanoparticle production easier and cheaper

by Prachi Patel

June 5, 2013

Nanometer-sized polymer particles are used widely in products such as paints, inks, and adhesives. They also have applications in medical diagnostics and drug delivery and hold promise for use in electronic and photonic devices. Now researchers have produced polymer particles of well-defined nanometer dimensions by blasting a mixture of monomers and water with sound waves (ACS Macro Lett. 2013, DOI: 10.1021/mz4001817). The method creates some of the smallest polymer nanoparticles possible without the use of soap-like compounds called surfactants. It could lead to a simpler, less costly way to produce polymer nanoparticles of distinct sizes.

The most common way to make size-controlled nanoparticles is to make an unblendable mixture, or emulsion, of the monomer, water, and a surfactant. The surfactant surrounds each monomer droplet, keeping the droplets apart before they get polymerized into solid nanoparticles. However, the surfactants have to be removed from the emulsion, making the process costly and difficult. Also the purity of the nanoparticles can suffer because some surfactant often remains in the polymer, says Mahito Atobe, a professor of environment and information science at Yokohama National University in Japan.

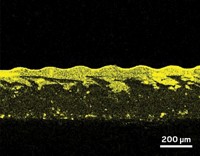

To avoid using surfactants, Atobe and his colleagues used sound waves to create the emulsion. They developed a technique that involves exposing a mixture of monomer and water to subsequently higher ultrasonic frequencies (Chem. Commun. 2011, DOI: 10.1039/C1CC10558B). Each step breaks up the monomer droplets into smaller ones.

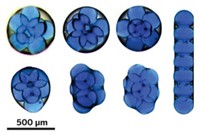

In the present work, they shook a mixture of methyl methacrylate (MMA) monomer and water at 20 kHz, 500 kHz, 1.6 MHz, and finally 2.4 MHz. The team used light scattering to measure the size of the droplets after each ultrasonication step. The last step resulted in a clear emulsion containing the smallest droplets ranging in diameter from 20 to 25 nm.

The researchers added ammonium peroxodisulfate to trigger the polymerization of the monomer droplets. By doing this to the emulsions from all four ultrasonications, they produced polymer nanoparticles of different sizes.

The clear emulsion containing the smallest MMA droplets formed poly(methyl methacrylate) nanoparticles with an average size of 129 nm. Other surfactant-free techniques to make polymer nanoparticles either yield larger particles at least 250 nm in diameter or require adding other monomers that can affect the properties of the final desired polymer.

Atobe says that the new method should be easy to scale up to produce commercial quantities. The team is now trying to extend the technique to other useful polymers.

Using ultrasonication to make an emulsion of small, uniform droplets of a monomer in water is interesting, says Mitchell A. Winnik, a professor of chemistry at the University of Toronto in Canada. Right now, polymerizing the monomer droplets yields nanoparticles that are larger than those of the original droplets, with sizes typical of the particles found in latex paint. Winnik says that the technique would be even more attractive if the droplet size could be preserved to make nanoparticles 20 to 25 nm in diameter.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter