Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Nanomaterials

Nanoparticle Coating For Glass Could Keep Car Cabins Cool

Materials Science: A new thin film containing indium tin oxide particles absorbs infrared light but is 80% transparent to visible light

by Melissae Fellet

September 24, 2013

Sunlight streaming through a car’s windows can make the temperature inside the cabin unbearable without air conditioning. A new transparent coating for glass made from metallic nanoparticles could help save energy used to keep car interiors cool by absorbing infrared light hitting the windows (ACS Appl. Mater. Interfaces 2013, DOI: 10.1021/am403011t).

Materials scientists have experimented with several types of coatings to block infrared light, each with a drawback that prevents them from reaching commercialization. Thin films of indium tin oxide (ITO) are transparent to visible light but absorb infrared radiation. Unfortunately, ITO films also block radio waves that carry calls and data to cellphones, making the materials impractical for car windows. To let radio waves in, some researchers turned to coatings with nanoparticles of ITO embedded in organic polymers. However, these coatings are not hard enough to withstand the wear and tear produced by car power windows. A silica-based coating containing ITO nanoparticles is stronger, but it requires high temperatures to manufacture.

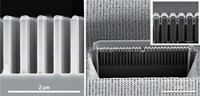

Kiyofumi Katagiri of Hiroshima University, in Japan, and his colleagues wanted to develop a strong nanoparticle-based material that could be made at a lower temperature. They first coated indium tin oxide nanoparticles containing 10% tin in octanoic acid. The researchers then suspended the hydrophobic nanoparticles in a silicon-containing polymer, perhydropolysilazane (PHPS). They spin-coated 10 layers of this mixture onto a glass surface and exposed the glass to ammonia vapor at 50° C to convert the PHPS into a silica polymer. The ITO nanoparticles end up embedded in the silica.

The resulting 0.75-μm-thick material is 80% transparent to visible light and absorbs 100% of infrared light at wavelengths longer than 1,400 nm. A silica-based coating containing ITO nanoparticles made by another group was thicker—about 2 μm—and blocked only infrared wavelengths longer than 1,600 nm. Absorbing a wider range of infrared light should keep a car cabin cooler, Katagiri says. The new material’s hardness is comparable to silica films without nanoparticles, so it should withstand the repeated forces created by power windows. Katagiri says one of his material’s limitations is that PHPS is expensive.

Hiromitsu Kozuka, a materials scientist at Kansai University, in Japan, says the straightforward processing at low temperatures and ambient pressure could make this coating practical for car windshields. But he points out that although exposing small pieces of glass to ammonia vapor is simple on a lab scale, on a large scale, it may be difficult to produce reproducible coatings.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter