Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Analytical Chemistry

A Sweet Solution For Controlling Fluidics In Paper Devices

Microfluidics: A bridge made of sugar can control how much fluid passes from a reservoir to another part of a paper device

by Erika Gebel Berg

November 26, 2013

Expensive laboratory devices and their expert handlers are often hard to come by in developing parts of the world. To help people in those regions run medical diagnostics or check water quality, scientists want to translate the functions of big pieces of equipment into simple and inexpensive paper-based devices.

A team of researchers now reports a way to expand the capabilities of these small analytical tools. They incorporated a dissolvable sugar bridge into a paper microfluidic device that acts as a valve, allowing the researchers to control the quantity of a fluid delivered to and from parts of the paper (Anal. Chem. 2013, DOI: 10.1021/ac4022677).

One type of assay run on paper devices is called a lateral flow test, which works like the basic home pregnancy test. Users add liquid sample to one spot on the device. The liquid then travels through capillary action down a paper strip to another spot containing reagents. A reaction between analytes and the reagents creates a color change, indicating the analytes’ presence.

However, lateral flow devices are pretty limited in what they can do analytically. Researchers such as Elain Fu of Oregon State University want to add new functionalities to the devices, such as the pump controls and valves used in conventional microfluidic devices. By adding in features that allow researchers to control the timing and amounts of liquids delivered, paper devices could look for more than one analyte in a sample or perform assays with more than a single step. For example, with the capability to handle multiple steps, researchers could include a way to amplify detection signals to perform more sensitive tests such as enzyme-linked immunosorbent assays (ELISA).

Fu and her team wanted to develop an automated shut-off switch for liquid flow in paper devices. Such a switch would allow users to deliver a specified amount of a fluid, perhaps containing a reagent for use in an assay, with minimal intervention, Fu says.

She and her team found the solution in the supermarket: a sugar cube. They thought that a sugar bridge, essentially a small rectangular sugar cube, between two parts of a paper device would eventually dissolve as fluid passed through, shutting off flow. By changing the bridge’s size and composition, researchers could control the amount of liquid delivered.

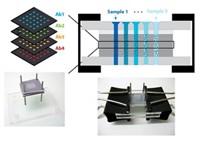

To test the idea, the researchers built a paper device that folds like a greeting card. On one half of the device, there is a reservoir and a paper strip runway separated by a gap. They put the sugar bridge on the device’s other half. Folding the card lays the bridge across the gap between the runway and a feeder strip connected to the reservoir.

They tested two sugars, trehalose and mannose, to make bridges in two widths, 3 mm and 6 mm. Another variable they played with was the material used to make the reservoir feeder strip, which brings liquid from the reservoir to the bridge. They tested nitrocellulose, glass fiber, and polyester. With different combinations of these three variables, the researchers found they could reliably deliver between 10 and 80 μl of dyed water through the bridge before it dissolved. All of the bridges dissolved within about five minutes.

With the proof-of-principle tests completed, Fu next plans to incorporate the sugar bridge into a paper device that can detect malaria.

Carlos D. M. Filipe of McMaster University recently reported a paper device with an “erodible polymeric bridge.” His bridges used different materials but were designed with a similar goal (Lab Chip 2013, DOI: 10.1039/c3lc50762a).

“Both studies provide interesting solutions to the challenge of self-powered, non-electrical off switches,” says Scott T. Phillips of Pennsylvania State University, who develops paper microfluidic devices. “Certainly this is a capability that my group would like to have.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter