Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Energy

Three Ways To Make High-Energy Batteries Last

Materials Science: With three new materials, lithium-sulfur batteries could have longer lifetimes and extend the range of electric vehicles between charges

by Katherine Bourzac

December 3, 2013

Batteries with lithium-sulfur electrodes theoretically could store four times more energy than conventional lithium-ion batteries, promising longer play times for electronics and more miles for electric cars between charges. Now researchers claim that commercialization of these batteries is within reach. With three new materials designs, they show that they can extend the batteries’ lifetimes while maintaining a high storage capacity (Nano Lett. 2013, DOI: 10.1021/nl402793z).

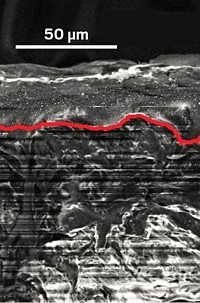

Researchers trying to design practical lithium-sulfur batteries have to contend with several problems. First, as the batteries charge and discharge, the lithium-sulfur cathodes release and absorb large quantities of lithium ions, which causes the electrodes to expand and contract in volume by about 80%, says Yuegang Zhang, a materials scientist at the Chinese Academy of Sciences. This can cause the cathode to break and separate from its electrical connections, stopping the flow of electricity.

The other challenges are chemical in nature. During the battery’s charging cycles, sulfur and lithium react, forming lithium polysulfides that are soluble in conventional electrolytes. As this sulfur dissolves away from the cathode, the battery’s energy-storage capacity drops. Also, the polysulfides spread throughout the battery, depositing on the anode. Because the compounds are electrical insulators, they decrease the amount of current that can flow through the device. As a result, the battery delivers weak bursts of power and takes a long time to recharge.

Unfortunately, addressing just one of these problems doesn’t lead to a practical battery, Zhang says. Collaborating with researchers at the Lawrence Berkeley National Laboratory, Zhang’s team tried to solve them all. “We had to combine a bunch of improvements,” he says.

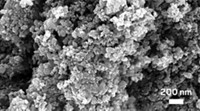

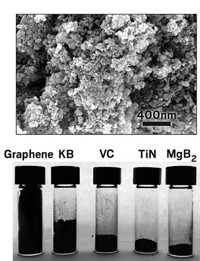

They started with a composite cathode material that Zhang’s group previously had made by coating sulfur on graphene oxide (J. Am. Chem. Soc. 2011, DOI: 10.1021/ja206955k). The carbon material is conductive, stretchy, and strong, so it increases the cathode’s durability as it expands and contracts. Graphene oxide also binds well to sulfur, preventing the sulfur from dissolving away when it reacts with lithium. To further confine sulfur to the cathode, they coated it with a surfactant called cetyltrimethylammonium bromide, which has a strong affinity for sulfur.

The researchers also used a rubberlike material for the binder that holds parts of the battery together. Unlike the conventional binder, polyvinylidene fluoride, which is brittle, the rubber material easily stretches and contracts. Finally, they used a new electrolyte consisting of a conventional organic electrolyte mixed with an ionic liquid. The ionic liquid helps prevent sulfur from leaving the cathode because polysulfides are not soluble in it.

Zhang’s team tested their new design in small coin cells, which are simple-to-build batteries that researchers normally work with in the lab and are commonly found in wristwatches or calculators. They used pure lithium metal as the anode.

The battery could be charged and discharged, or cycled, 1,500 times, with no degradation in performance. Its initial energy storage capacity was 500 watt-hours per kilogram of battery material. Conventional lithium-ion batteries store about 200 Wh/kg, and the U.S. Department of Energy’s target for electric vehicle batteries is 400 Wh/kg. After 1,000 cycles, the storage capacity dropped to 300 Wh/kg—still beating conventional lithium-ion batteries. Based on these results, Zhang believes that this technology is now ready for commercialization, and he’s seeking industrial partners to scale up the battery design.

Jie Liu, a chemist at Duke University, says, “This is a big step forward.” This work shows that the problem of long-term stability in lithium-sulfur batteries can be overcome, he says.

Now more work is needed on the other electrode, the anode. Liu says pure lithium metal is probably not practical because of fire risk, and that other high-energy-storage anodes under development, such as silicon anodes, will need to be paired with the sulfur cathodes.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter