Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Custom Catalyst Resists Oxidation

Tuning catalysts to selectively expose preferred crystal faces may protect catalyst from oxidation and deactivation

by Mitch Jacoby

March 31, 2014

| A version of this story appeared in

Volume 92, Issue 13

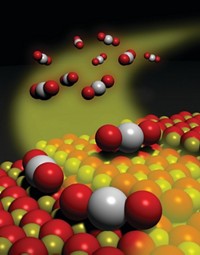

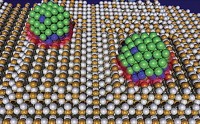

Solid-state catalysts mediate a large fraction of commercial chemical reactions. Typically, these chemistry workhorses lose some of their ability to transform reactants to products as a result of various aging processes. One such process converts active metallic catalyst sites to inactive metal oxides. That undesirable change requires frequent chemical reactor maintenance, which is costly. A team led by Jason Hattrick-Simpers and Jochen Lauterbach of the University of South Carolina, Columbia, report a strategy for avoiding that problem. In a proof-of-concept study, the team shows that cobalt-based catalysts that drive Fischer-Tropsch chemistry, a process for making synthetic fuels from CO and hydrogen, can be tailored to resist oxidation by water vapor, a common problem. The trick is selectively exposing oxidation-resistant crystal faces by preparing the catalyst as elongated nanorods instead of nanoparticles (Chem. Commun. 2014, DOI: 10.1039/c4cc01021c). Catalysis tests and spectroscopy analyses show that in contrast to cobalt-based nanoparticles, which become oxidized and lose catalytic activity quickly in the presence of steam, nanorods remain largely unaffected. The group attributes the oxidation resistance to the more favorable reduction potential of the nanorod surfaces relative to those of nanoparticles.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter