Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

Depolymerizing Lignin

Formic acid transforms oxidized paper and pulp by-product into aromatics

by Bethany Halford

November 10, 2014

| A version of this story appeared in

Volume 92, Issue 45

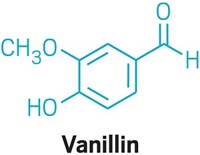

Lignin, a component in the cell walls of plants, makes up almost 30% of all the organic carbon on Earth. But because the aromatic biopolymer is notoriously recalcitrant, it’s usually treated as a waste product of the paper and pulp industry and burned, sending all those valuable aromatics up in flames. Now, Shannon S. Stahl and colleagues at the University of Wisconsin, Madison, have come up with a way to depolymerize lignin into low-molecular-mass aromatics, with a yield of 60% by weight

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter