Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Microscopic Insights Into Roman Mortar

Mineral plates prevent cracks from propagating through the mortar used in 1,900-year-old Trajan’s Markets

by Bethany Halford

December 22, 2014

| A version of this story appeared in

Volume 92, Issue 51

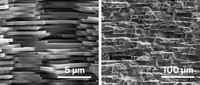

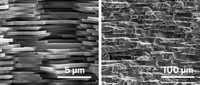

The ancient Roman office and shopping complex known as Trajan’s Markets is a monument to resilient architecture. More than 1,900 years old, this structure has withstood moderate earthquakes and floods. One secret to its staying power, scientists say, is the mechanical resilience of the mortar that binds together cobble-sized pieces of brick and porous rock that make up the market buildings. Researchers led by Marie D. Jackson of the University of California, Berkeley, used computed tomography and synchrotron X-ray microdiffraction to study a reproduction of the Roman mortar as it cured (Proc. Natl. Acad. Sci. USA 2014, DOI: 10.1073/pnas.1417456111). Over the course of 180 days, the mortar made from a simple recipe of hydrated lime and volcanic ash developed platelike crystals of strätlingite, a durable calcium-aluminosilicate mineral. These mineral plates provide reinforcement and prevent cracks from propagating through the mortar. The researchers observed these same plates of strätlingite in samples of the mortar taken from Trajan’s Markets. The Roman mortar suggests routes to making sturdy concrete via a process that releases less carbon dioxide than the standard process for making modern Portland cement.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter