Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Light-Emitting Diode Can Stretch More Than Twice Its Length

Optoelectronics: A transparent, elastic electrode made of a silver nanowire network soldered with graphene oxide enables stretchy LEDs

by Prachi Patel

February 11, 2014

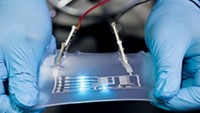

Researchers have made a light-emitting diode that remains brightly lit while they repeatedly stretch it (ACS Nano 2014; DOI: 10.1021/nn405887k). Such elastic light emitters could enable new types of devices, such as flexible cell phone screens or wearable electronics.

The key behind the stretchy LED is a transparent electrode composed of a conductive network of silver nanowires dotted with graphene oxide flakes. The graphene oxide acts like solder, wrapping around the junctions between the nanowires and forging the joints together. This soldering ensures that when the electrode stretches, the nanowires don’t rub against each other, which can reduce conductivity, says Qibing Pei, a materials scientist at the University of California, Los Angeles.

To make the electrodes, Pei and his colleagues soaked a piece of glass coated with silver nanowires in a dispersion of graphene oxide flakes. Electrostatic forces make the flakes bond strongly with the nanowire junctions. The researchers then coated the nanowires with a urethane acrylate monomer, which they allowed to cure. When they peeled off the resulting polymer film, the nanowire-graphene-oxide network was embedded. The elastic films are about 5% more transparent and 35% more conductive than the indium-tin-oxide-coated polyethylene films typically used as electrodes for flexible optoelectronic devices, the researchers report.

Finally, the team made an organic LED by sandwiching a white-light-emitting polymer between two of the stretchable conductive films. The researchers were able to pull the device to more than double its original size while it still glowed—but they could do that only once. They could stretch the device 100 times if they limited the pulls to 40% beyond the device’s original size.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter