Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Carbon Nanotube Coating Boosts Battery Performance

Materials: Adding a thin film of multiwalled carbon nanotubes to a plastic membrane helps lithium-sulfur batteries last longer

by Katherine Bourzac

June 4, 2014

Lithium-ion batteries with cathodes made of sulfur can, in theory, store much more energy than rechargeable batteries sold today. That means longer times between charges for electric cars and mobile devices. Now, researchers in Texas have shown that adding a layer of carbon nanotubes to one component of the battery could help overcome a host of practical challenges posed by sulfur cathodes (J. Phys. Chem. Lett. 2014, DOI: 10.1021/jz5006913).

Lithium-sulfur battery cathodes can store five times more energy than the positive electrodes in today’s best commercial cells. When a lithium-ion battery is discharged and recharged, lithium ions move between the two electrodes and drive current through an external circuit. The more lithium ions the cathode can hold, the more energy the battery can store. Sulfur cathodes can store a lot of energy because they can take up and release a large amount of lithium.

However, that means the cathode volume fluctuates by 80%, which can short out the battery and jeopardize safety. What’s more, lithium ions react with sulfur to form lithium polysulfides at the cathode throughout the lifetime of the battery. These compounds travel through the electrolyte to the anode, taking sulfur away from the cathode and thus rapidly depleting its energy-storage capacity.

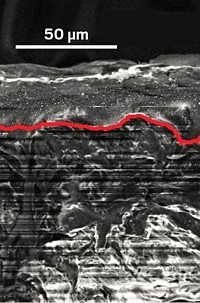

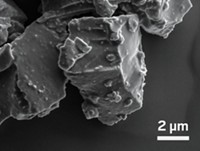

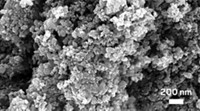

To solve these problems, many researchers are working on new formulations of the sulfur cathode materials. Arumugam Manthiram, a chemist and director of the Texas Materials Institute at the University of Texas, Austin, has taken a different approach: adding a layer of carbon between the cathode and the separator, a membrane that allows electrons and lithium ions to flow between the two battery electrodes. Carbon films are conductive, stretchy, and strong, and they help block polysulfides. Mantiram’s group first tried putting a piece of carbon paper between the cathode and separator, but that adds weight. So to keep batteries as light and compact as possible, they decided to coat a conventional battery separator with a thin film of commercially available multiwalled carbon nanotubes.

To do this, they suspended the nanotubes in an alcohol solution and used vacuum filtration to pull the nanotubes onto the surface of the separator. They dried the coated separator and then used it to make small battery cells for testing in the lab.

Researchers often blend sulfur, which is an insulator, with carbon to increase the cathode’s conductivity, but this cuts down on energy storage. Because carbon nanotubes are very conductive, the researchers were able to use a total weight percentage of about 65% sulfur in the battery. This high proportion of sulfur led to a battery that discharged 1,324 mA-hours per gram, close to the theoretical storage capacity of a Li-S battery. Importantly, the storage capacity didn’t fade much over time. “For a lab battery, the performance we get is pretty good, and the coating process should be low cost and easily scalable,” Manthiram says. The Li-S batteries were only tested through 300 charge and discharge cycles; a real-world battery needs to last through thousands of such cycles, he notes.

“This is an interesting processing-based approach to improve the performance of Li-S batteries without the need for new materials synthesis for the electrodes or electrolyte,” says Jeffrey Pyun, a chemist at the University of Arizona who is also working on these types of batteries. However, he points out that the cost of the carbon nanotubes has to be taken into account. Manthiram says there may be cost issues with using this particular material, but that it should be possible to make the coatings with a less expensive form of carbon.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter