Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Environment

A New Spin On Nanocellulose

Nanomaterials: Life-cycle assessment guides approach to extract, functionalize, and orient cellulose nanofibers from food waste

by Stephen K. Ritter

May 18, 2015

| A version of this story appeared in

Volume 93, Issue 20

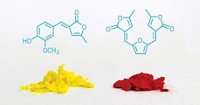

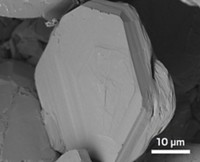

Scientists in Switzerland have developed an approach for producing cellulose nanofibers starting from vegetable food waste such as pomace left over from carrot juice production. But along the way, the team led by Roland Hischier of the Swiss Federal Laboratories for Materials Science & Technology (Empa) performed a life-cycle assessment to compare environmental impact, performance, and economic data against those for other nanocellulose preparation methods. The assessment helped the team select the processes in the new method to ensure it will be commercially competitive (ACS Sustainable Chem. Eng. 2015, DOI: 10.1021/acssuschemeng.5b00209). Cellulose nanofibers are biodegradable materials derived from renewable resources such as cotton, coconuts, and wood pulp that are being developed as alternatives to carbon or glass fibers for food packaging, medical applications, and organic-based displays. Because nanocellulose is only just beginning to be commercialized, the production methods are still being worked out. Hischier and his colleagues looked at energy use, choice of starting material, water and solvent use, and waste trade-offs. They selected enzymes over chemical acid hydrolysis to depolymerize and isolate the cellulose, identified an approach to functionalize the fiber surface with a polymer coating, and chose a wet-spinning method over commonly used electrospinning to orient the fibers and spin them into yarn. The team also looked at other details, such as whether carrot pomace was best burned for energy production, used as a fertilizer, or as a source of nanocellulose.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter