Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Biobased Chemicals

Interest In Biobased Levulinic Acid Grows

Green Chemistry: Italian firms pursue development of intermediate from cellulosic feedstocks

by Melody M. Bomgardner

March 5, 2015

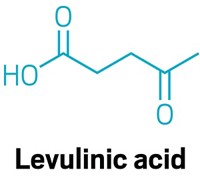

Two Italian chemical firms have launched projects to produce levulinic acid from biomass. The companies say their technologies will lower costs and turn a niche chemical into an attractive new building block for products used in crop protection, coatings, solvents, and fuels.

GFBiochemicals, based in Milan, says it will begin commercial production of levulinic acid from a starch feedstock this summer in Caserta, Italy. Capacity will start at 2,000 metric tons per year and scale up to 8,000 metric tons by 2017, the firm says. It aims to switch to cellulose-based feedstock in 2016. GFB’s executives, veterans of big companies such as Solvay and Air Products, say they have the expertise to sell the chemical for new applications where it can replace petroleum-derived inputs.

Meanwhile, Bio-on, a maker of biodegradable polyhydroxyalkanoate resins, says it will collaborate with the sugar company Eridania Italia to produce levulinic acid from sugar by-products. Eridania will invest roughly $2 million; the firms contend the molecule has immediate potential in biodegradable plastics.

Fans of levulinic acid would like to see it follow in the footsteps of succinic acid, another biobased intermediate that is being commercialized by BioAmber, Myriant, and Reverdia. Both substances were on a list of the 12 most promising chemicals from biomass put out a decade ago by the U.S. Department of Energy. But whereas succinic acid is made from sugars and requires fermentation, levulinic acid can be derived directly from biomass using an acid-catalyzed hydrolysis process.

As now synthesized from maleic anhydride, levulinic acid is rather expensive to produce, limiting its use to low-volume applications such as fragrances and food additives. For the biobased version to take off, companies will have to produce it at low cost and work with customers to identify new uses, says Adrian Higson, lead consultant on biobased products at the U.K.’s National Non-Food Crops Centre.

Those firms could look to U.S.-based Segetis, which sells ingredients for personal care and cleaning products based on levulinic ketals. The company operates a biobased levulinic acid pilot plant in Minnesota.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter