Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Making Silk Optical Devices With Photolithography

Materials: A manufacturing method taken from the semiconductor industry could help scale up production of high-tech silk devices

by Katherine Bourzac

April 24, 2015

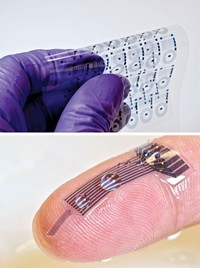

Researchers have demonstrated the use of photolithography to pattern simple optical devices out of silk proteins (ACS Appl. Mater. Interfaces 2015, DOI: 10.1021/acsami.5b01380).

Fibers from the cocoon of the silkworm Bombyx mori have long been fashioned into lustrous textiles and medical sutures. Lately, researchers have shown silk’s potential as a material for making optical devices, such as lenses, that are flexible and biodegradable. Such devices could be used in implants for delivering light-triggered therapies, or in environmentally friendly sensors. “If you want to make green photonics and electronics, those are overwhelming reasons to use silk,” rather than the typical plastic or glass, says Vamsi K. Yadavalli of Virginia Commonwealth University.

Researchers at Tufts University pioneered the field of making silk optical devices by molding and other methods. In 2013, Yadavalli’s group demonstrated a potentially faster and less expensive way to build with silk: photolithography (Adv. Mater., DOI: 10.1002/adma.201302823). This high-volume manufacturing method is used to make computer chips but isn’t typically used to build with biological materials such as proteins.

Yadavalli and colleagues make silk proteins compatible with photolithography by decorating them with photoreactive acrylate groups. The researchers then coat the photoreactive proteins onto a surface and expose them to a flash of ultraviolet light through a patterned mask. The illuminated acrylates cross-link, and the unexposed parts can be rinsed away.

In the current study, Yadavalli’s team used photolithography to make two simple optical devices: a flat lens called a Fresnel zone plate and an iridescent pattern. When making optical devices, it’s best to be able to pattern features hundreds of nanometers in size, comparable to the wavelength of visible light. Currently this technique can create features 1 μm in size; therefore, Yadavalli is working on improving the resolution.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter