Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

ACS Meeting News: Automated Flow Technique Makes Length- And Sequence-Specific Polymers

by Stu Borman

August 19, 2015

Traditional synthetic polymers contain a distribution of chain lengths and monomer sequences. For applications such as molecular electronics, however, scientists want to create polymers of a specific sequence and length—a difficult task.

Frank A. Leibfarth, Jeremiah Johnson, and Timothy Jamison at MIT have now developed Flow-IEG (flow synthesis and iterative exponential growth), a semi-automated coupling and modification technique that makes it possible to easily synthesize sequence- and length-defined linear and branched non-biological polymers. The researchers reported the new method this week during two Division of Polymer Chemistry presentations at the ACS national meeting in Boston.

Scientists have produced non-biological polymers of defined sequence and length previously. But to do so, they have had to prepare individual batches via time-consuming, multi-step syntheses, or they have used solid-phase synthesis (SPS), which adds monomers to resin beads sequentially. SPS typically yields under 1 g of polymer per day for a single synthesizer and generally produces short chain lengths. In contrast, the new Flow-IEG system makes up to about 60 g of polymer per day and produces longer chain lengths than SPS can easily handle.

Unlike SPS coupling reactions, Flow-IEG reactions do not require large excesses of monomer or oligomer to generate defined polymer chains and do not use solid or soluble resins that must be thrown away. However, “SPS is still the method of choice if each monomer is different and a researcher only requires a few milligrams of material, as is the case in many biomedical applications,” Jamison said.

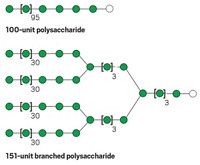

The MIT team demonstrated the technique by combining up to three different oligomers into 16-mer polymer chains that would be difficult to access with traditional polymerization techniques (Proc. Natl. Acad. Sci. USA 2015, DOI: 10.1073/pnas.1508599112).

Batch-synthesizing periodic homogeneous polymers is “very painful” for the grad students who often carry it out, said Jean-François Lutz, head of a precision macromolecular chemistry group at the University of Strasbourg. Flow-IEG “greatly simplifies the process and makes it much more convenient.”

Polymer synthesis expert Craig J. Hawker of the University of California, Santa Barbara, agreed, noting that currently even the most optimized iterative processes typically require weeks of skilled labor. “Having a flow system do the work in substantially less time and with greater reliability is a real breakthrough,” he said. “Flow-IEG could help unlock the vast potential of synthetic polymers in numerous applied disciplines.”

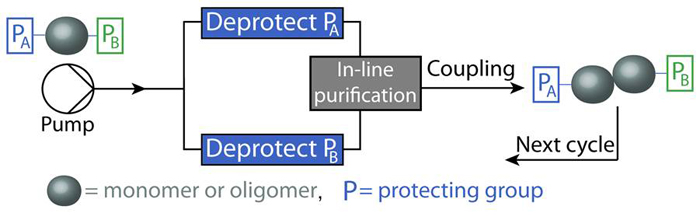

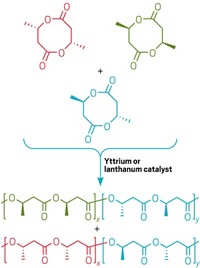

Flow-IEG extends IEG, a known batch-synthesis technique, by running it in a multistep flow format. In each step, one of two different protecting groups on each substrate is removed and the substrates are purified and coupled into an end-protected product. Each cycle nearly doubles the molecular weight of the polymer. A variation called IEG+ adds stereocontrol and side-chain functionalization to the approach, making it possible to incorporate new functional groups into growing polymers in a stereospecific manner.

The MIT researchers have not yet commercialized the technology but may do so in the future. They are trying to improve the flow system to achieve full automation and are looking into incorporating new coupling chemistries. “Our vision is to ultimately make it easy for non-experts to produce complex stereo- and sequence-defined macromolecules for a variety of applications,” Johnson said.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter