Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Separations

Nanoparticle Heating Distills Ethanol From Water

Separations: How light-driven heating could make distillation cheaper and more energy efficient

by Prachi Patel

November 19, 2015

A new method for heating liquid mixtures could reduce the energy required for distillation. Researchers have found that shining laser light on gold nanoparticles in an ethanol-water mixture vaporizes the ethanol without bringing the whole mixture to a boil (Nano Lett. 2015, DOI: 10.1021/acs.nanolett.5b02804). The approach also works with sunlight and would be especially suitable for use in remote areas, the researchers say.

In conventional distillation, a liquid mixture is heated, and its components vaporize preferentially according to their vapor pressures. The vapor, which is enriched in the lower boiling compounds, is then condensed. The process is “extraordinarily energy intensive,” says Naomi J. Halas, professor of electrical and computer engineering at Rice University. In bioethanol production, for example, distillation accounts for 75–80% of energy use.

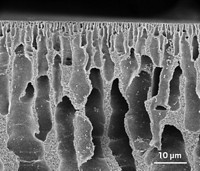

To reduce the energy needed, Halas and her colleagues turned to nanoparticles. A decade ago, Halas pioneered a process that relies on nanoparticles with a metal shell that absorb certain wavelengths of light and generate intense heat in a small region around them. In 2012, the Rice team showed that focusing sunlight on aqueous solutions of 100-nm-diameter particles with silica cores and gold shells could generate steam (ACS Nano, DOI: 10.1021/nn304948h).

They have now applied the same trick to mixtures of alcohol and water. They use an optical fiber to shine 15-W near-infrared laser light on vials of ethanol-water mixtures with the same silica-gold nanoparticles mixed in. Within a few minutes, the nanoparticles heat up, vaporizing an ethanol-enriched mixture from the surrounding liquid. The researchers separate the vapor and condense it. The relatively large nanoparticles are not carried into the ethanol vapors, Halas says.

The technique also prevents the formation of an azeotrope, a problem with ethanol and water mixtures. Ethanol-water mixtures are impossible to separate completely via conventional distillation without using special drying agents. The researchers tested the nanoparticle technique with mixtures of ethanol and water in different ratios. Because they did not form azeotropes, the resulting ethanol fractions had higher purity than those from a traditional distillation.

The researchers have not calculated how much less energy the nanoparticle technique needs compared with traditional distillation. But, Halas says, the technique could work using sunlight, bypassing grid power altogether. And carbon nanoparticles, which also heat up in response to light, would provide a cheaper option than gold shell nanoparticles.

Halas does not envision the method being used for massive distillation columns in the chemical industry any time soon. Rather, she says, it could be useful for quickly getting rich alcohol fractions on a smaller scale as part of a more complex separation process.

Nanoparticle-based heating has been mainly explored for medical applications until now, says Laura I. Clarke, a professor of physics at North Carolina State University. The new work demonstrates that the method can enhance a commercially important process like ethanol distillation. But more than being a novel application, “this means that not all heating is equivalent,” she says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter