Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Electronic Materials

Sketchable, Stretchable Circuits

Electronics: A regular pen can be filled with ink made of silver salt and rubber to make stretchy, conductive traces

by Prachi Patel

December 18, 2015

Want to string together some holiday lights? Or test an idea for a circuit? A new elastic silver ink could let users jot down electrical circuits and wiring on walls and paper with a regular ballpoint pen (ACS Nano, 2015, DOI: 10.1021/acsnano.5b05082).

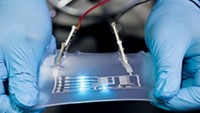

The ink, made of silver salt and adhesive rubber, sticks to various surfaces, and the resulting circuits stay conductive despite repeated bending. If the wiring breaks, retracing the lines would fix it. “It’s a very simple method to make hand-drawn stretchable circuits,” says Jun Yang, a professor of mechanical and materials engineering at the University of Western Ontario. “You can easily make wearable electronics,” he says. “Just hand draw a circuit to make a personalized T-shirt.”

Conductive silver inks have been on the market for a few years and have been used to print flexible circuits. But these inks aren’t suitable for pens because they are made of silver nanoparticles, which tend to aggregate and clog the pen tip, Yang says. Other researchers have reported pen-written circuits that use silver nanoparticle-based inks. But these inks also clog over time or work only on specific substrates. Plus, they don’t produce stretchable wiring.

Yang and his colleagues concocted a nanoparticle-free ink by mixing silver trifluoroacetate salt and styrene-isoprene-styrene (SIS), a rubber adhesive, into butanone solvent. They also added small amounts of additive solvents such as dimethylacetamide to improve the ink’s fluidity.

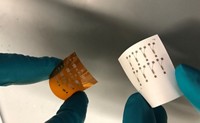

The team used a ballpoint pen filled with the ink to draw lines on various substrates such as paper, plastic, and a stretchable SIS film. Once the ink was dry, they brushed a solution of formaldehyde and sodium hydroxide on the lines, which reduced the silver salt to metallic silver nanoparticles, making the ink conductive. The lines have to be traced over and reduced multiple times to have good conductance. They were more conductive when written on a smooth surface like plastic.

As a demonstration, the researchers made a heart-shaped string of 14 LED lights connected with pen-written traces. The lights stay lit even when the rubber substrate is bent, twisted, and stretched.

Yang says that the concept could be used to make inks with other metals such as copper. The researchers have launched a startup, Nectro, to manufacture and sell a dual-tipped pen with a writing tip and an erasing tip containing ink that allows users to correct mistakes and redraw a circuit.

The simplicity of hand-drawn circuits is technologically attractive, says Nicholas A. Kotov, a professor of chemical engineering at the University of Michigan. Compared with previous efforts to produce hand-drawn circuits, the novelty of this work is the conversion of liquid ink to a solid, nanoparticle-based conductor after writing, he says. “The adaptability of this technology to ball pens that do not clog is quite remarkable.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter