Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Laser-Guided Liquid Marbles

Microfluidics: Nanoparticles and laser light could lead to remote-controlled microreactors and liquid robots

by Matt Davenport

January 18, 2016

| A version of this story appeared in

Volume 94, Issue 3

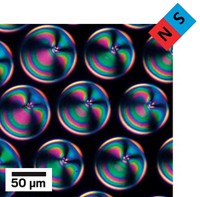

Shooting marbles is no longer just a game for researchers at Harbin Institute of Technology. Led by Qinmin Pan, the team has developed nanoparticle-encased microdroplets—so-called liquid marbles—that can be steered through water using laser light (ACS Appl. Mater. Interfaces 2015, DOI: 10.1021/acsami.5b09952). This technique could lead to remotely controlled microreactors and microrobots. To make the liquid marbles, the Harbin team rolled hydrophobic chloroform microdroplets over a bed of iron oxide-polydopamine core-shell nanoparticles in a beaker of water. The nanoparticles cling to the interface between the two liquids and form a coating around the droplets. The researchers then shot individual marbles with near-infrared laser light, heating and vaporizing small pockets of the chloroform within. The vapor creates a bubble that sticks to the marble, making it more buoyant. Eventually, the marble lifts off in the beaker. The team can manipulate a marble vertically and laterally by controlling the intensity and position of the laser beam. Orlin D. Velev, a chemist at North Carolina State University, calls this microdroplet manipulation method “simple, elegant, and easy to implement.”

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter