Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Hyperlens lights a new path to nanofabrication

Metamaterial lens beats diffraction limit and could bolster photolithography

by Matt Davenport

November 15, 2016

| A version of this story appeared in

Volume 94, Issue 46

Photolithography has established itself as a standard in the semiconductor industry and as a stalwart in research labs by helping shrink electronics and other devices over decades.

But there are limits to how small the light-based technique can make things, and pushing those limits can be a pricey proposition, says Natalia M. Litchinitser of the University at Buffalo, SUNY.

Using a so-called hyperlens, she and her team have given photolithography a new twist that could potentially cut costs while overcoming one of the method’s more infamous limitations (Nano Lett. 2016, DOI: 10.1021/acs.nanolett.6b04175).

Researchers have been developing hyperlenses for years, but primarily for imaging. The lenses can help resolve small or closely spaced objects that would otherwise be blurred by the diffraction of light. Because hyperlenses overcome this diffraction limit, they could also improve fabrication techniques that use light, notably photolithography, scientists have posited. Litchinitser and her team are among the first to experimentally back up that hunch.

In conventional photolithography, light shoots through a mask that controls where an underlying photosensitive layer, or photoresist, is exposed to—and shadowed from—light. This transfers whatever pattern is on the mask to the substrate beneath it.

To shrink the structures that photolithography can make, researchers have had to create masks with ever-smaller features. And to resolve these smaller mask features, researchers have needed shorter wavelength light, usually in the ultraviolet regime. Precision masks and energetic UV light add to the cost and effort requirements of photolithography.

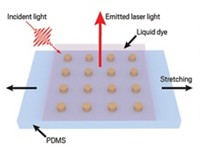

The hyperlens developed by Litchinitser and her team offers a route to nanofabrication using visible light and larger mask features. It consists of more than a dozen alternating layers of conducting silver and insulating titanium oxide, each about 30 nm thick, made using electron beam evaporation.

The “extreme anisotropy” of this design enables the lens to encode a mask’s features as a downsized blueprint within the light’s electromagnetic field, Litchinitser says. This scaled-down design is what ultimately develops in the photoresist.

Litchinitser says her team is the first to show that hyperlenses can overcome the diffraction limit in photolithography. Because no known natural material can accomplish this feat, the team’s hyperlens is a metamaterial by definition.

Although the hyperlens doesn’t produce smaller features than photolithography that uses UV light and precision masks yet, Litchinitser believes her team is off to a promising start. Xiangang Luo of the Chinese Academy of Sciences, who’s also introducing hyperlens technology to photolithography, agrees. “This implies that patterns with features far beyond the diffraction limit can be fabricated with ease,” Luo says.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter