Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Materials

Molybdenum disulfide transistors break through a performance limit

Devices made out of the two-dimensional semiconducting material show that it can live up to its theoretical promise

by Katherine Bourzac

September 26, 2016

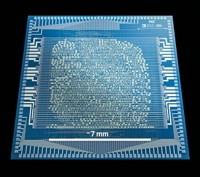

A new design has enabled researchers to make the best performing transistor yet from two-dimensional molybdenum disulfide. They say the results show the material has the right stuff to compete with silicon in the future—though many technological challenges still stand in its way (Nano Lett. 2016, DOI: 10.1021/acs.nanolett.6b02713).

Atomically thin 2-D materials like MoS2, graphene, and phosphorene have unique electronic properties that make them promising as potential replacements for silicon, or at least as an intrinsically flexible alternative to this rigid material. But before that can happen, researchers have to show that the performance of devices made from ultrathin MoS2 can approach or surpass that of silicon.

MoS2 has high electrical mobility and is a semiconductor, which means it can be made into transistors that switch between conducting and insulating states, providing the 1s and 0s of the digital logic that’s at the heart of computing.

But so far, MoS2’s promise has not been realized. “It’s clear what should be possible, but it’s not clear how to get there,” says Andras Kis, an electronics engineer at the Swiss Federal Institute of Technology, Lausanne, who is not involved in the current work.

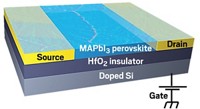

One of MoS2’s main handicaps is a problem called contact resistance, says Xiangfeng Duan, a chemical engineer at the University of California, Los Angeles. To make a transistor, researchers not only need a semiconducting material, they must also add electrodes that apply a voltage to switch the material between states. They’ve had a difficult time figuring out how to build electrical contacts on MoS2. Pure metal contacts have high resistance when built on the material, and previous work on hybrid contacts incorporating other materials, such as graphene, required harsh methods such as plasma etching that harmed the thin sheets of MoS2. Such damage impedes the flow of current, making a transistor with a high contact resistance. This slows down the transistor’s switching speed, which would ultimately make for a sluggish circuit.

To solve this problem, on top of a flake of MoS2 they placed a silicon nanowire about 80 nm in diameter to serve as a mask, then overlaid the flake and wire with graphene. On top of that they deposited a layer of nickel to form the electrodes. Then they used sticky tape to mechanically remove the coated nanowires—which bulged above the surrounding surface. This left behind an exposed MoS2 channel to serve as the active area of a transistor, connected to hybrid graphene-nickel electrodes on either side. This mechanical approach doesn’t damage the channel like etching can.

The graphene buffers the underlying MoS2 in two ways: It prevents the nickel deposition process from causing any chemical or mechanical damage, and it eases the flow of current between the other materials. These transistors have a record-low contact resistance of 0.21 kiloohm-μm.

Kis says this low contact resistance is an important milestone for the material, since it’s seven to 10 times as good as previously demonstrated devices. It’s difficult to do an apples-to-apples comparison with silicon, since today’s chips use silicon transistors about one-tenth as small, and the technology is mature. Duan says that although ultrathin MoS2 does not perform quite as well as silicon in his lab demo, he believes the work shows the material to be a contender for computer processors, or for flexible or wearable devices.

That will be a long time in coming, though, since the transistors were handmade using sticky tape. What’s important about the current work, Kis says, is to demonstrate that this kind of electrical performance is possible.

The next step for Duan’s group is to demonstrate that the low contact resistance can translate to high switching speeds, which is what electrical engineers and circuit designers ultimately care about.

This article has been translated into Spanish by Divulgame.org and can be found here.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter