Advertisement

Grab your lab coat. Let's get started

Welcome!

Welcome!

Create an account below to get 6 C&EN articles per month, receive newsletters and more - all free.

It seems this is your first time logging in online. Please enter the following information to continue.

As an ACS member you automatically get access to this site. All we need is few more details to create your reading experience.

Not you? Sign in with a different account.

Not you? Sign in with a different account.

ERROR 1

ERROR 1

ERROR 2

ERROR 2

ERROR 2

ERROR 2

ERROR 2

Password and Confirm password must match.

If you have an ACS member number, please enter it here so we can link this account to your membership. (optional)

ERROR 2

ACS values your privacy. By submitting your information, you are gaining access to C&EN and subscribing to our weekly newsletter. We use the information you provide to make your reading experience better, and we will never sell your data to third party members.

Synthesis

More reaction steps are better for making biomass-derived pentanediol

A longer synthetic pathway surprisingly offers a less-expensive way to make the polymer building block

by Stephen K. Ritter

April 3, 2017

| A version of this story appeared in

Volume 95, Issue 14

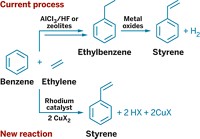

Creating high-value coproducts along with biofuels is an important part of helping biobased chemicals become economically viable so they can complement petroleum-derived chemicals. But this is a tricky proposition because hundreds of interrelated compounds exist in both the petrochemical and biomass chemical pathways. That means sorting through many possible reactions to find optimal routes to target products. In one of the latest examples, George A. Huber, James A. Dumesic, and coworkers at the University of Wisconsin, Madison, have found a new way to make 1,5-pentanediol, a building block for polyurethane and polyester plastics. An economic analysis of the possible routes surprised the team: A longer, multistep route turns out to cost about 40% less than a shorter, more direct route owing to better yield and lower catalyst and utility expenses (ChemSusChem 2017, DOI: 10.1002/cssc.201700178). The synthesis of biobased 1,5-pentanediol has focused on hydrogenating hemicellulose-derived furfural to tetrahydrofurfural alcohol (THFA), followed by hydrogenolysis of the alcohol to 1,5-pentanediol. The drawback of this approach is low catalytic activity, leading to high catalyst cost. The Wisconsin team found that converting THFA to 2-hydroxytetrahydropyran (HY-THP) and then to 1,5-pentanediol via a ring-opening isomerization and hydrogenation is better because the hydrogenation rate of HY-THP is 80 times as fast as THFA hydrogenolysis. The researchers say the new route is applicable to 1,4-butanediol and 1,6-hexanediol as well.

Advertisement

CORRECTION: The reaction scheme in this story was updated on April 6, 2017, to correct an error in the final 1,5-pentanediol structures.

Join the conversation

Contact the reporter

Submit a Letter to the Editor for publication

Engage with us on Twitter